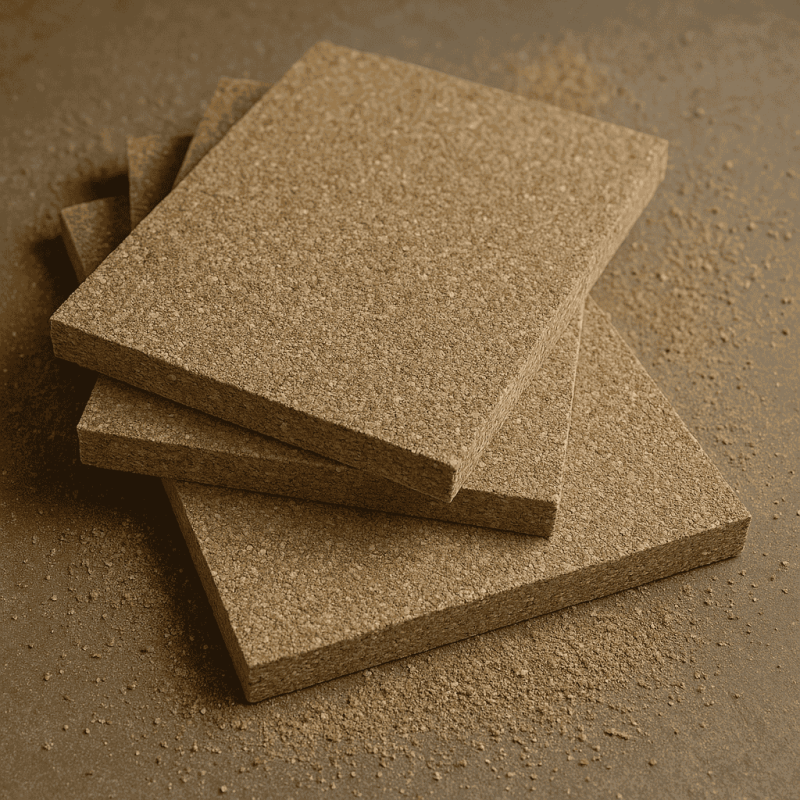

Vermiculite boards | VIREboard

Our VIREboard vermiculite boards have a density of 375–700 kg/m³ and a maximum application temperature of 1.150 °C. They are often used in wood-burning stoves and boilers and are ideally suited for high temperature loads.

- Density

- 375 kg/m³ | 475 kg/m³ | 600 kg/m³ | 700 kg/m³

- Strength

- 10mm | 15mm | 20mm | 25mm | 30mm | 35mm | 40mm | 45mm | 50mm | 55mm | 60mm | 65mm | 70mm | 75mm | 80mm | 90mm | 100mm | 105mm

- Dimension

- 1000 x 610 mm | 1000 x 750 mm | 1260 x 1000 mm | 2440 x 1220 mm

-

Cost-oriented

Technically excellent and cost-oriented solution.

Nontoxic

Light, non-toxic, fiber-free, odorless and acid-resistant.

Fireproof

Depending on the product variation, application temperatures up to 1100 °C.

CHARACTERISTICS

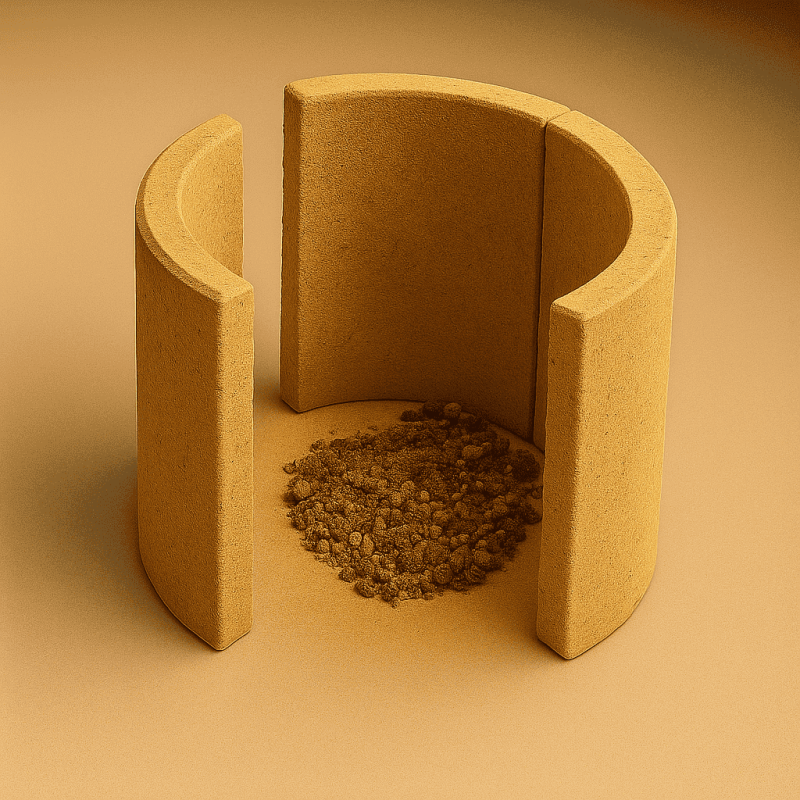

High mechanical strength – ideal for combustion chamber linings

Insulation capacity for doors, covers, and other combustion components

Temperature resistance up to 1,100 °C, even with thermal shocks

Low thermal conductivity and high electrical resistance

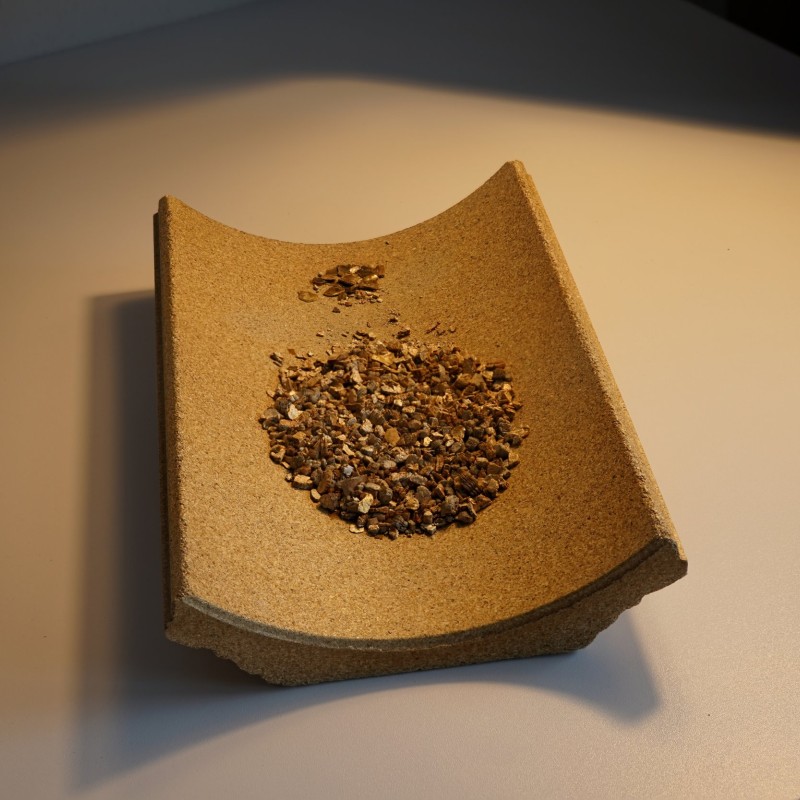

Possible applications & custom manufacturing

Possible applications & custom manufacturing

Our vermiculite boards are used not only in furnace construction, but also in the metal, steel, and aluminum industries. Thanks to their versatility, they are suitable for both private fire protection and demanding industrial processes.

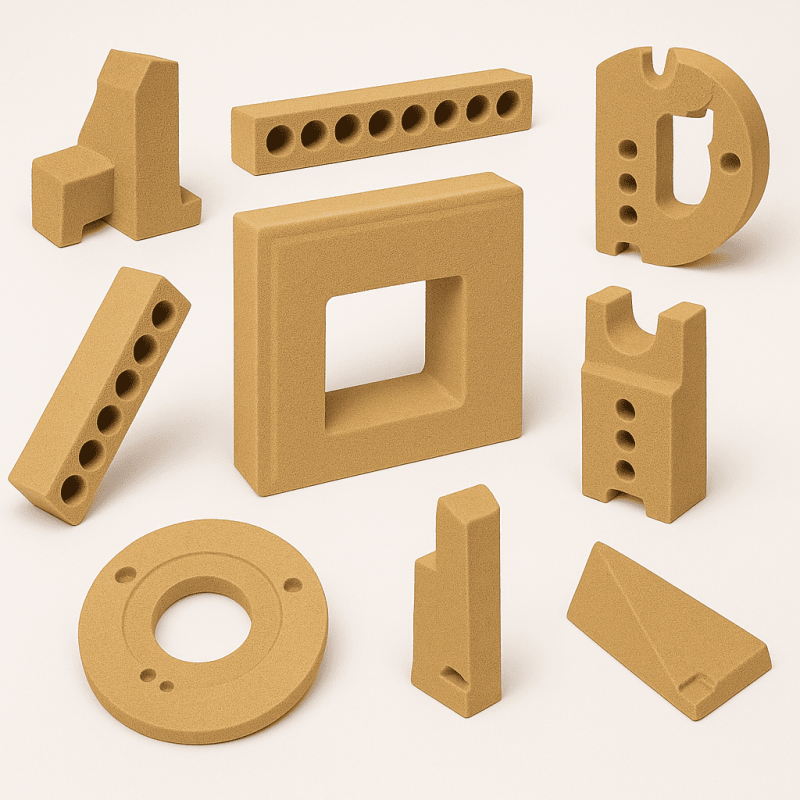

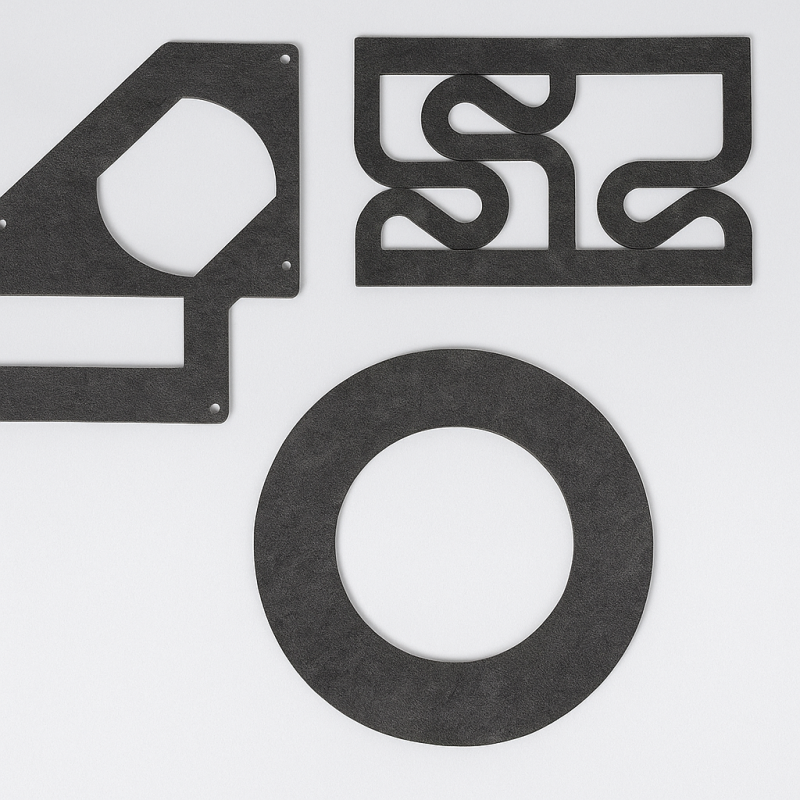

A particular advantage is that the boards can be processed into various shapes and sizes – exactly according to customer requirements and specifications. This means you receive tailor-made solutions for your applications, from wood-burning stoves and chimneys to industrial plants.

👉 Do you require special dimensions or custom-made products? Contact us – we will advise you personally and manufacture the right vermiculite boards for your project.

Benefits

- different densities depending on the application

- unclassified material

- Cost efficient

- Technically excellent

- Light

- Nontoxic

- Fiber free

- Odorless

- Acid resistant

- High temperature resistant

TECHNICAL DETAILS

PROPERTIES

Application Temperature 1100°C Melting point > 1300°C Panel thickness tolerance +/- 1mm Tolerance length/width +/- 2,5mm linear post-shrinkage Aprox. 1% Thermal expansion coefficient 11,0 x 10⁶ K¹ Loss on ignition 1025°C: 7% HS fare Nr. 6809.90.00 Colour Sand CHEMICAL ANALYSIS

SiO2 46,0% TiO2 0,7% Fe2O3 5,5% Al2O3 7,0% MgO 19,0% CaO 3,5% Na2O 0,2% K2O 10,0% Vermilite 375 Vermilite 475 Vermilite 600 Vermilite 700 Density 375 kg/m3 475 kg/m3 600 kg/m3 700 kg/m3 Cold compressive strength 1,3 N/mm2 2,5 N/mm2 4,2 N/mm2 4,5 N/mm2 Flexural strength 0,3 N/mm2 0,8 N/mm2 1,6 N/mm2 2,0 N/mm2 Overall porosity 85% 81% 76% 74% THERMAL CONDUCTIVITY

Temp. (W/m°K) (W/m°K) (W/m°K) (W/m°K) 200°C 0,12 0,14 0,16 0,19 400°C 0,15 0,17 0,18 0,20 600°C 0,16 0,19 0,20 0,21 800°C 0,19 0,20 0,22 0,22 Frequently Asked Questions (FAQ)

What are the typical applications of VIREboard Vermiculite Boards?

Our VIREboard Vermiculite Boards are primarily used in wood stoves, fireplaces, boilers, as well as in the metal, steel, and aluminum industries. They are ideal for firebox linings, doors, covers, and other high-temperature applications.

Up to what temperature can the boards be used?

The VIREboard boards are suitable for temperatures up to a classification temperature of 1,150 °C and remain stable and reliable even under thermal shocks.

Can the boards be manufactured to custom dimensions?

Yes, we offer special sizes and custom cuts tailored precisely to your requirements. Please contact us for an individual offer.

Are the boards safe for health?

Yes, our boards are lightweight, fiber-free, non-toxic, odorless, and acid-resistant. They are safe to handle and can be used without concern.

What thicknesses and densities are available?

The VIREboard boards are available in thicknesses from 10 mm to 105 mm and in densities from 375 to 700 kg/m³. This ensures we provide the right solution for every application.

-

Since 2001, KS Kneissl & Senn Technologie GmbH

has been producing insulation materials and seals for a wide range of applications up to a temperature range of 1600 °C. A diverse range of machinery (CNC 5-axis milling, plotting, punching, sewing, water jet cutting, vacuum forming, etc.) enables us to shape a wide variety of materials for you. The main materials include: glass fibers, aramid fibers, mineral fibers, biosoluble fibers, ceramic fibers, silicate fibers, vermiculite, calcium silicate, microporous materials, elastomers (rubber, silicone, silicone foam, etc.), etc.

The company has been ISO9001 certified since 2009, currently in accordance with the 2015 revision of the standard.