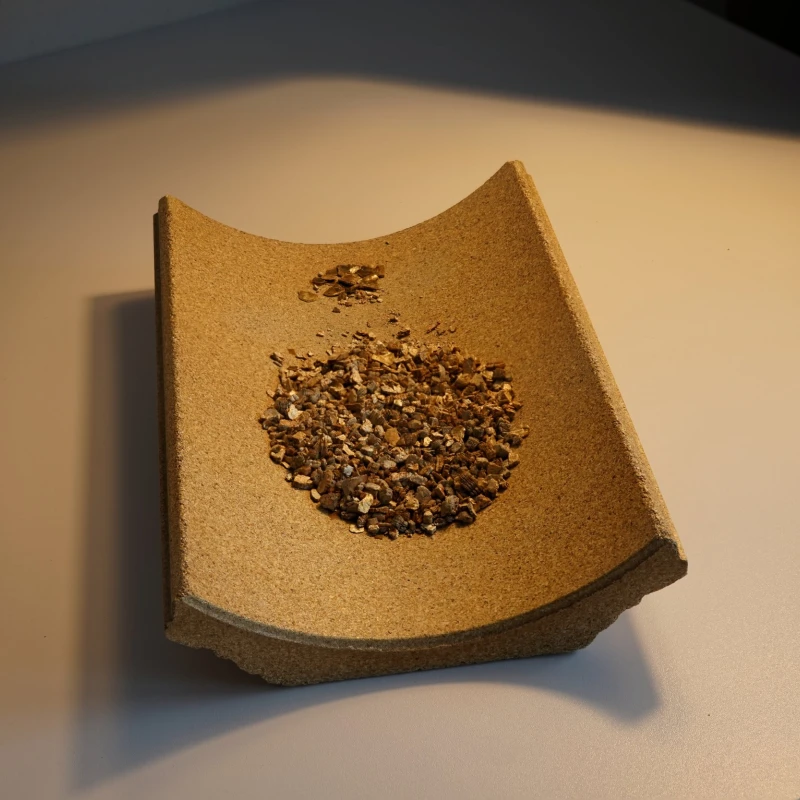

Vermiculite pressed parts

Vermiculite pressed parts are refractory components designed for continuous temperatures up to 600 °C and short-term peaks of 1100 °C. Produced using a pressing process, they are especially suitable for large series. This makes them a cost-effective, safe, and durable solution for industries such as furnace construction, boilers, automotive, and mechanical engineering.

- PRODUCT VARIATIONS

- According to customer specifications

-

Cost-oriented

Technically excellent and cost-oriented solution.

Nontoxic

Light, non-toxic, fiber-free, odorless and acid-resistant.

Refractory

Depending on the product variation, application temperatures up to 1100 ° C.

TECHNICAL DETAILS

PROPERTIES

Application Temperature 1100°C Melting point > 1300°C Panel thickness tolerance +/- 1mm Tolerance length/width +/- 2,5mm linear post-shrinkage Aprox. 1% Thermal expansion coefficient 11,0 x 10⁶ K¹ Loss on ignition 1025°C: 7% HS fare Nr. 6809.90.00 Colour Sand CHEMICAL AVERAGE ANALYSIS

SiO2 46,0% TiO2 0,7% Fe2O3 5,5% Al2O3 7,0% MgO 19,0% CaO 3,5% Na2O 0,2% K2O 10,0% Vermilite 375 Vermilite 475 Vermilite 600 Vermilite 700 Density 375 kg/m3 475 kg/m3 600 kg/m3 700 kg/m3 Cold compressive strength 1,3 N/mm2 2,5 N/mm2 4,2 N/mm2 4,5 N/mm2 Flexural strength 0,3 N/mm2 0,8 N/mm2 1,6 N/mm2 2,0 N/mm2 Overall porosity 85% 81% 76% 74% THERMAL CONDUCTIVITY

Temp. (W/m°K) (W/m°K) (W/m°K) (W/m°K) 200°C 0,12 0,14 0,16 0,19 400°C 0,15 0,17 0,18 0,20 600°C 0,16 0,19 0,20 0,21 800°C 0,19 0,20 0,22 0,22 Typical Applications

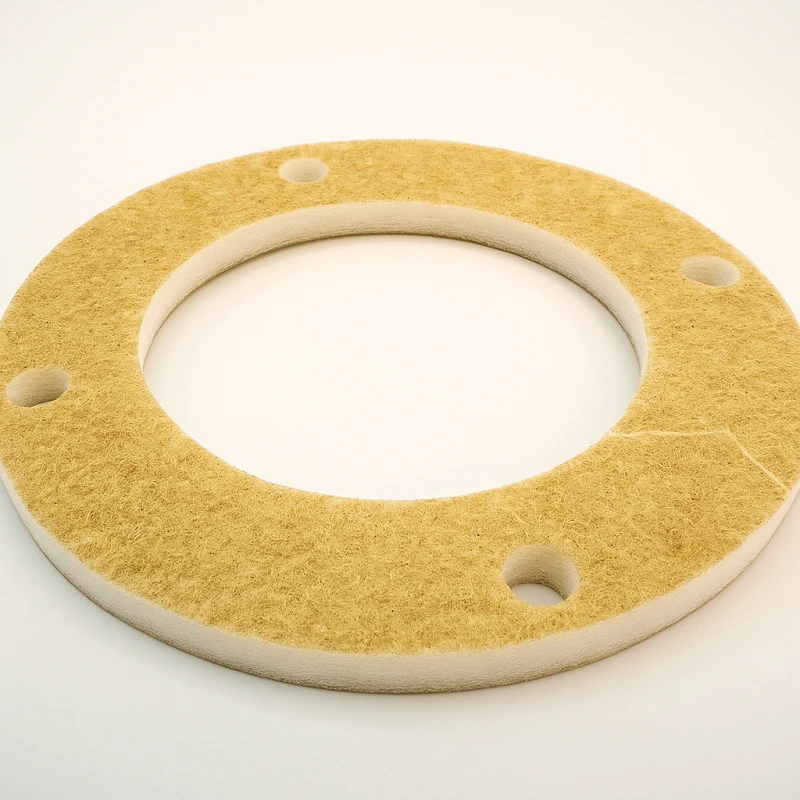

Industrial furnaces & boilers → flange seals, insulation plates

Automotive → exhaust and heat protection components

Stove & fireplace construction → fireproof plates and seals

Mechanical engineering → precision pressed parts in large quantities

Benefits

- Heat resistant: up to 600 °C continuous, 1100 °C short-term

- Safe: fiber-free, non-toxic, formaldehyde-free

- Durable: moisture- and acid-resistant

- Customizable: produced to customer specifications, optional with press-fit nuts

- Economical: ideal for high-volume production

FAQ – Frequently Asked Questions about Vermiculite Pressed Parts

What temperatures can Vermiculite pressed parts withstand?

Continuously approx. 600 °C, short-term up to 1100 °C.

Can custom shapes be manufactured?

Yes, pressed parts are produced according to customer specifications – optionally with press-fit nuts.

What is the advantage compared to ceramic fibers?

Vermiculite pressed parts are fiber-free, non-toxic and safe for health – with the same heat resistance.

-

Downloads

Data sheet Vermilite2000 Isolation products

Product properties, typical applications and availabilities.

Datasheet Vermilite2000 Isolation board RD375

Product properties, typical applications and availabilities.

Datasheet Vermilite2000 Isolation board RD475

Product properties, typical applications and availabilities.

Datasheet Vermilite2000 Isolation board RD600

Product properties, typical applications and availabilities.

Datasheet Vermilite2000 Isolation board RD700

Product properties, typical applications and availabilities.

Senn Group Information Catalog

Refractories, seals, foundry supplies, conveyor chains, compensators, plain bearings, lubricants, metal parts, and logistics/FTL

-

Since 2001, KS Kneissl & Senn Technologie GmbH

has been producing insulation materials and seals for a wide range of applications up to a temperature range of 1600 °C. A diverse range of machinery (CNC 5-axis milling, plotting, punching, sewing, water jet cutting, vacuum forming, etc.) enables us to shape a wide variety of materials for you. The main materials include: glass fibers, aramid fibers, mineral fibers, biosoluble fibers, ceramic fibers, silicate fibers, vermiculite, calcium silicate, microporous materials, elastomers (rubber, silicone, silicone foam, etc.), etc.

The company has been ISO9001 certified since 2009, currently in accordance with the 2015 revision of the standard.