Are you looking for a reliable, local contract manufacturing partner for steel / stainless steel / aluminum / plastic?

Do you need finished metal parts in the Tyrolean lowlands that meet your exact requirements? Then you've come to the right place! We offer tailor-made solutions, manufactured with state-of-the-art technology and the highest precision.

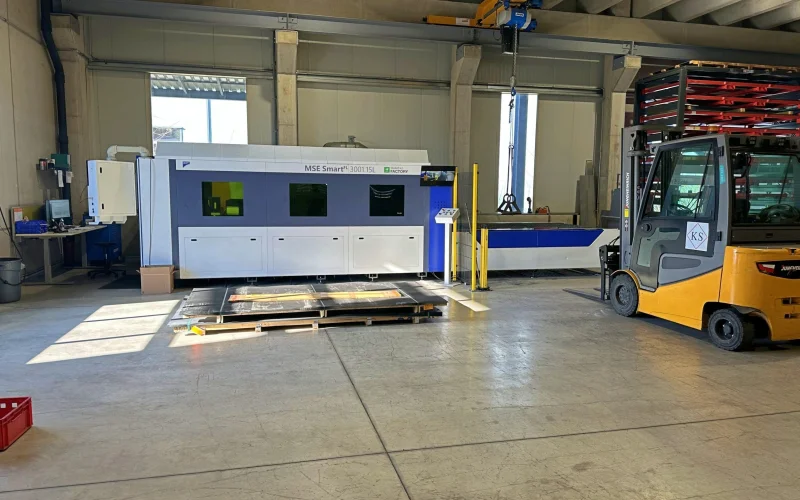

Since 2022, we have had a completely new machine park at our Erl site, which enables us to process a wide range of steel and stainless steel grades.

laser cutting

Precision and efficiency in laser cutting of metal

Laser cutting of metal is the ideal solution for precise results in metalworking. State-of-the-art laser technology achieves clean, accurate cuts with minimal material loss. Whether steel, aluminum, or stainless steel, laser cutting offers unmatched accuracy and is perfect for demanding designs and intricate details. The process is extremely efficient, shortens production times, and ensures excellent edge quality.

Our state-of-the-art laser systems enable customized solutions that are tailored precisely to your needs. From industrial manufacturing to artistic metalwork, laser cutting offers impressive flexibility and allows complex shapes to be produced with the highest precision. Thanks to automated controls and state-of-the-art equipment, we guarantee reliability and speed for every project. Trust in our expertise to achieve flawless results that meet the highest quality standards.

MSE SmartFL 3001.15L

mittels O2 und N2

The video gives you an impression of how laser cutting works. With the MSE SmartFL 3001.15L system, we can process sheet metal up to 3000 x 1500 mm in size. Black steel up to a thickness of 20 mm, stainless steel up to a thickness of 12 mm.

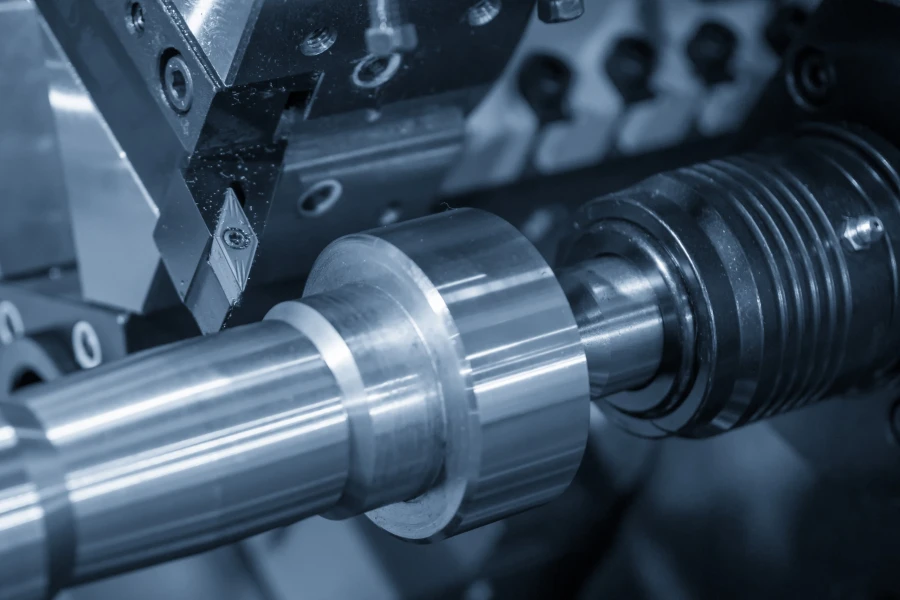

Metal milling

Precision work through CNC milling

Metal milling is a fundamental part of modern manufacturing, enabling the design and customization of metal components with the highest precision. Using advanced milling machines, material is removed from metal surfaces to create intricate designs, precise dimensions, and high-quality finishes. Whether for prototyping or mass production of components, metal milling ensures consistency, reliability, and adaptability in various industries such as automotive, aerospace, and construction.

Our state-of-the-art milling facilities enable customized solutions tailored to the specific requirements of each project. From simple cuts to complex geometries, our team of experts ensures the highest precision at every stage. By combining technical expertise and innovative technology, we offer efficient and cost-effective milling services that bring your vision to life with excellence and accuracy.

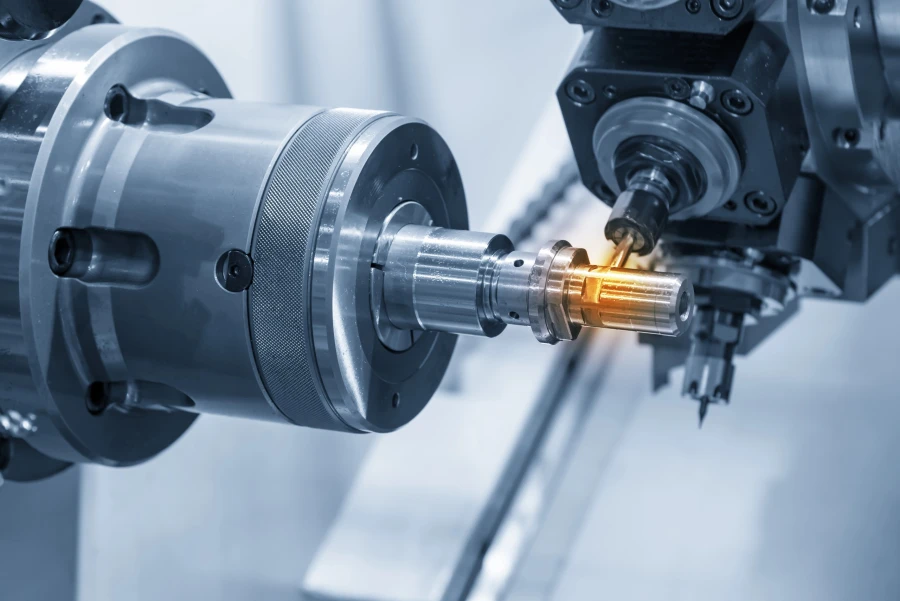

Metal turning

Precision and reliability in CNC turning

Metal turning is an essential machining process that enables the precise shaping of cylindrical components with maximum accuracy. Modern lathes achieve smooth surfaces and precisely defined dimensions, making this technique perfect for manufacturing components in industries such as automotive, aerospace, and mechanical engineering. Whether for small, delicate workpieces or large industrial components, turning ensures consistent quality, efficiency, and first-class results.

Our sophisticated lathes enable tailor-made solutions that are precisely tailored to your requirements. From single pieces to series production, we focus on delivering flawless results with minimal material loss. By combining technical expertise and innovative technology, we offer cost-effective and reliable turning services that meet the highest industry standards. See our precision for yourself and rely on first-class metalworking.

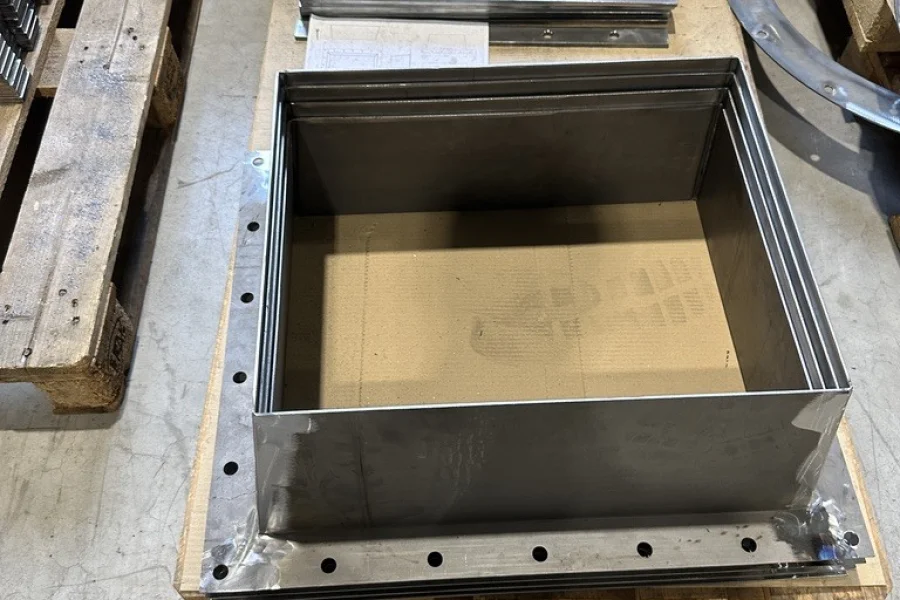

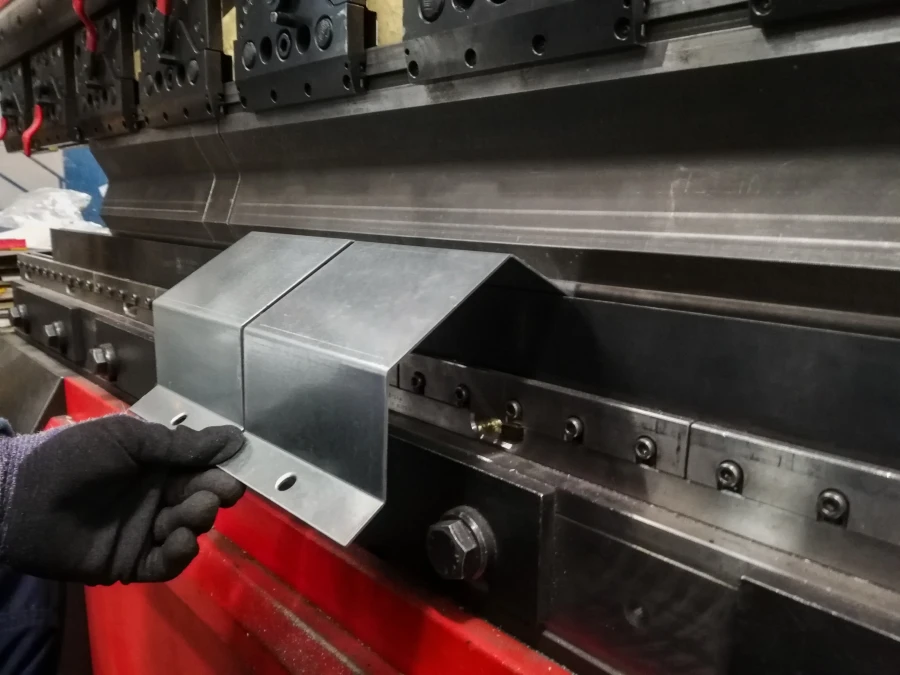

Bending

Precision and stability in machine bending

Machine bending/metal bending is an efficient process that ensures precise shapes and high stability in metalworking. With the help of modern bending machines, metal sheets and profiles are seamlessly formed without compromising their structural integrity. Whether for industrial, architectural, or automotive applications, machine bending offers accurate and reliable results, reduces production time, and minimizes material waste.

Our state-of-the-art equipment and experienced specialists guarantee customized bends that are perfectly tailored to your requirements. Thanks to our ability to process various metals such as stainless steel or aluminum, we deliver reliable results for small and large-scale projects. By combining precise technology and innovative processes, we ensure stable, flawless bends that meet the highest industry standards.

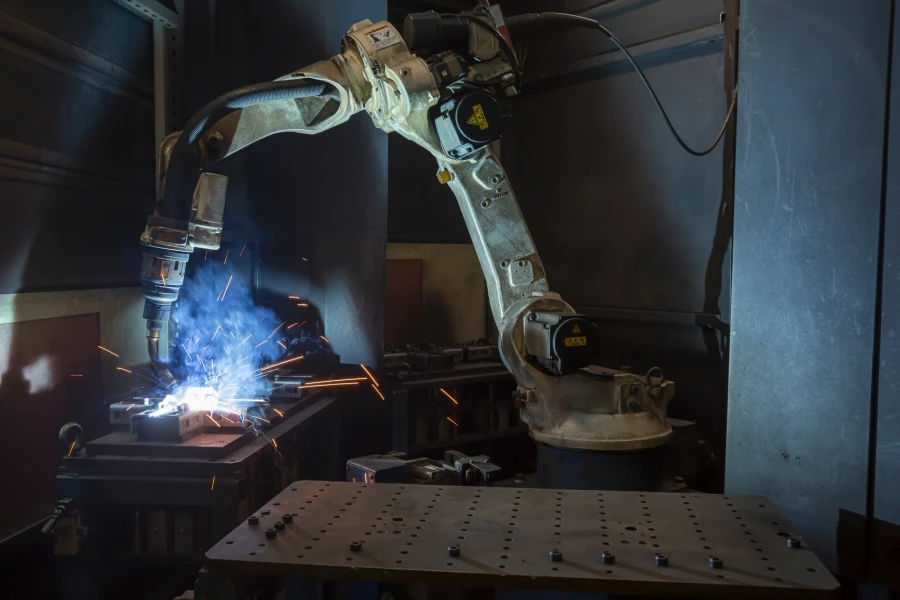

Welding

Precision and stability during welding

Our metal welding services offer high-quality solutions for a wide range of industrial applications. With comprehensive expertise in MIG/MAG and TIG welding, we guarantee robust, reliable joints that meet the highest standards of durability and precision. Whether manual or automated, our welding processes guarantee excellent results for different metals and components.

For efficient production and consistent quality, we use a robot-assisted welding cell for MIG/MAG welding, which enables the processing of components up to 800 mm. This ensures precise, repeatable, and economical processes with minimal material loss. Whether for customized projects or large-scale production, our experienced team and state-of-the-art technology deliver first-class welding solutions that are precisely tailored to your requirements.

Machine park

Precision and performance thanks to state-of-the-art machinery

Here you will find impressions of our machine park. This is constantly being expanded with additional machines. If you have any questions about the machines and processing options, please contact us.

We look forward to helping you with your project.

About us

Who are we?

Metallfertigung is the sales brand for contract manufacturing orders in the (stainless) steel sector of RBS Kompensator GmbH. At RBS Kompensator GmbH, we manufacture expansion joints and, since 2021, metal components such as flanges, connectors, and baffle plates.

RBS Kompensator GmbH has been a member of the SENN Group since 2013.

Key figures for the Group

- Group turnover: EUR 40 million

- Employees: 100

- One-stop shop: Refractories, seals, foundry supplies, conveyor chains, expansionjoints, plain bearings, lubricants, metal parts, and logistics/FTL

- Locations in Austria and Germany

- Founded in 2001

Job highlights

Your job. Your opportunity. Your future. We offer you more than just a job—with us, you can develop, grow, and make a difference.