Aspen Aerogel ®

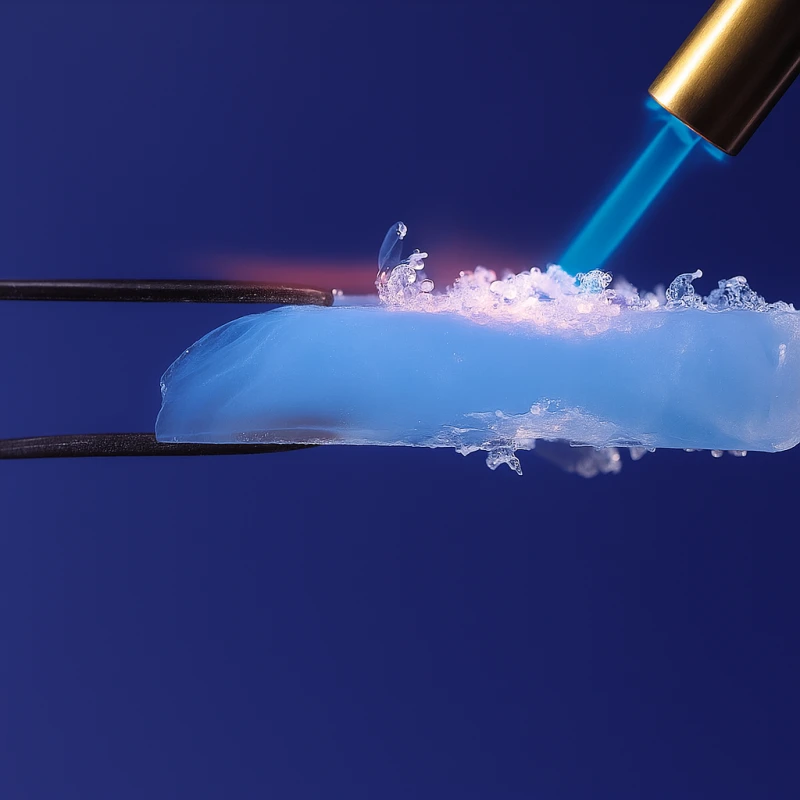

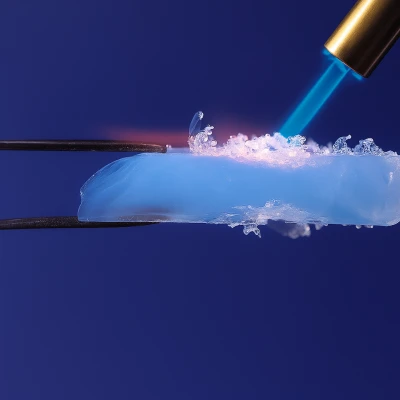

The material is based on advanced Aerogel technology – one of the lightest solid materials in the world – delivering superior insulation and energy savings even under extreme conditions.

- Types

- Pyrogel® HPS | Pyrogel® XTE | Pyrogel® XTF | Cyrogel® Z | Cyrogel® x201

-

Thermal power

Superior thermal performance, savings in logistics.

Reduced thickness

Reduced thickness and profile - Physically robust and impact resistant.

Environmentally safe

Ecologically safe, hydrophobic and yet breathable.

Why Choose Aspen Aerogel from us?

The SENN Group has decades of expertise in refractory systems and high-temperature insulation.

We provide expert advice and complete system solutions – from individual products to full project support.Key Advantages of Aspen Aerogel

Outstanding thermal insulation up to 650 °C

Up to 80 % thinner than conventional insulation materials

Hydrophobic yet breathable – moisture-resistant

Easy to cut, shape and install

Long-lasting and reusable

Reduced installation time = lower costs

Applications

Aspen Aerogel is ideal for a wide range of industrial insulation solutions:

Petrochemical & refinery systems

Steam and process pipelines

Heat exchangers, tanks and vessels

Power generation facilities

Offshore & marine installations

Aerospace & cryogenic equipment

Its compact design and superior performance make it perfect for tight spaces and critical temperature zones.

Product types

Produkt Dicke (mm) Wärmeleitfähigkeit (mW/m-K) Max. Temp. (°C) Anwendung Pyrogel® HPS ASTM C1728 10 22 650 Optimized for high temperature hydrocarbon & chemical processing, steam pipes, vessels and equipment, gas and steam turbines, removable blankets Pyrogel® XTE ASTM C1728 5 10 22 650 CUI defense, medium to high temperature processes, pipes, vessels and equipment, district energy steam networks, Aerospace and defense systems Pyrogel® XTF 10 22 650 Passive “pool fire” and passive “jet fire” protection for industrial and commercial applications, relief system sizing (API 521) Cyrogel® Z ASTM C1728 5 10 17 120 Sub-ambient and cryogenic pipelines, vessels and equipment, gas liquefaction & re-gasification facilities Cyrogel® x201 5 10 17 200 Sub-ambient including refrigerated appliances, cold storage and aerospace Häufig gestellte Fragen (FAQ)

How does Aerogel differ from traditional insulation?

Aerogel delivers up to five times better thermal performance at a fraction of the thickness and weight.

Is it water-resistant?

Yes – Aspen Aerogel is hydrophobic and repels liquid water while remaining vapor-permeable.

Can it be used outdoors?

Absolutely. With proper jacketing or coating, it is perfect for outdoor and offshore applications.

-

Datasheet Pyrogel® HPS

Product properties, typical applications and availabilities.

Datasheet Pyrogel® XTE

Product properties, typical applications and availabilities.

Datasheet Pyrogel® XTF

Product properties, typical applications and availabilities.

Datasheet Cyrogel® Z

Product properties, typical applications and availabilities.

Senn Group Information Catalog

Refractories, seals, foundry supplies, conveyor chains, compensators, plain bearings, lubricants, metal parts, and logistics/FTL

-

Since 2001, KS Kneissl & Senn Technologie GmbH

has been producing insulation materials and seals for a wide range of applications up to a temperature range of 1600 °C. A diverse range of machinery (CNC 5-axis milling, plotting, punching, sewing, water jet cutting, vacuum forming, etc.) enables us to shape a wide variety of materials for you. The main materials include: glass fibers, aramid fibers, mineral fibers, biosoluble fibers, ceramic fibers, silicate fibers, vermiculite, calcium silicate, microporous materials, elastomers (rubber, silicone, silicone foam, etc.), etc.

The company has been ISO9001 certified since 2009, currently in accordance with the 2015 revision of the standard.