Cerablanket™ | Ceramic Fibre Mats

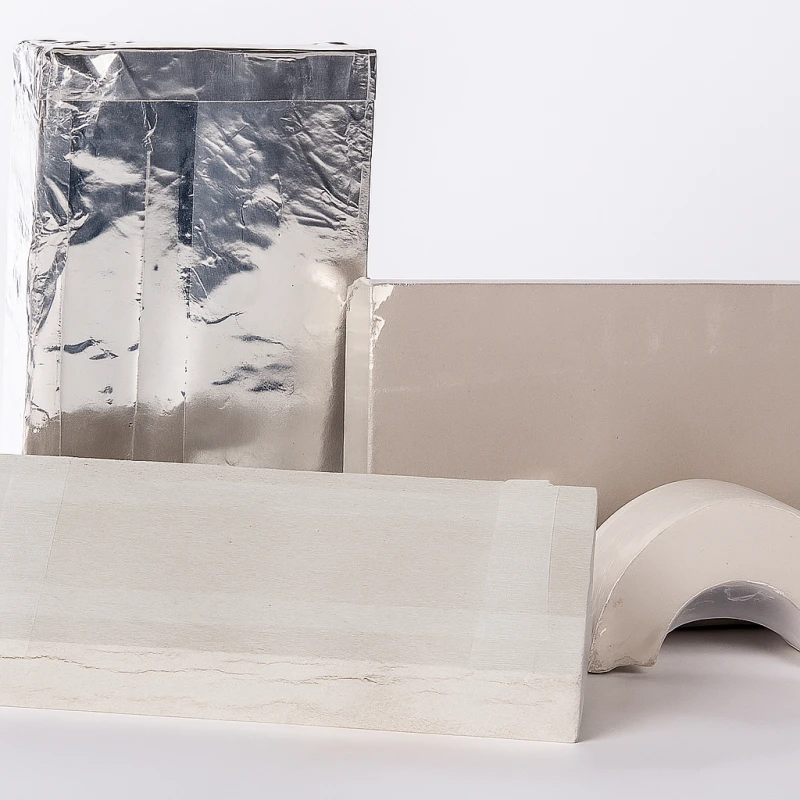

Cerablanket™ is a premium, needled ceramic fiber blanket manufactured from spun fibers (Cerafiber™).

It provides outstanding thermal insulation, high tensile strength, and exceptional chemical stability — suitable for continuous service up to 1177 °C and classification temperatures up to 1315 °C.

- Thickness (mm)

- 6mm | 10 mm | 13mm | 19mm | 25mm | 38mm | 50mm

- Density / volume weight (kg / m³)

- 64 kg / m³ | 96 kg / m³ | 128 kg / m³ | 160 kg / m³

-

Strength

Excellent handling / processing strength.

Heat resistance

Resistance to temperature changes & resistance to chemicals.

THERMAL CONDUCTIVITY

Low thermal conductivity & heat storage.

Key Features & Advantages

High temperature resistance up to 1315 °C

Low thermal conductivity and excellent heat storage capacity

High tensile strength & resilience, even after exposure to heat

Chemically inert & fireproof – no smoke or fumes when heated

Available in multiple densities and thicknesses

Excellent acoustic absorption properties

Thermal shock resistance and flexibility during installation

Material Description

Cerablanket™ blankets are lightweight, needled insulation mats made from high-purity alumino-silicate ceramic fibers (RCF/ASW).

They are completely inorganic, non-combustible, and maintain stability even under extreme thermal cycling.These materials are suitable for industrial furnaces, kilns, and process equipment where reliable, long-term insulation is critical.

Applications

Cerablanket™ is designed for use in a wide range of high-temperature industrial applications, including:

Furnace and kiln linings

Chimneys, flues, incinerators, and reformers

Process heaters, turbines, and exhaust ducts

Boilers, catalytic reactors, and chemical process units

Acoustic and thermal insulation systems

Fire protection and heat shielding

TECHNICAL DETAILS

Chemical Analysis

Al2O3 46,0 % SiO2 54,0 % ZrO2 - Others Traces Physical Properties

Colour White Classification Temperature (°C) 1315 Operating Temperature (°C) 1177 Specific Heat capacity (Kj/kg*K) 1,13 linear shrinkage (% after 24h)

1000 °C 1,5 1100 °C 2,2 1200°C 3,0 Density 64 kg/m³ 96 kg/m³ 128 kg/m³ 160 kg/m³ Thermal conductivity at 200°C 0,07 W/m°K 0,06 W/m°K 0,06 W/m°K - 400°C 0,12 W/m°K 0,11 W/m°K 0,10 W/m°K 0,09 W/m°K 600°C 0,20 W/m°K 0,16 W/m°K 0,15 W/m°K 0,13 W/m°K 800°C 0,30 W/m°K 0,23 W/m°K 0,20 W/m°K 0,18 W/m°K 1000°C 0,43 W/m°K 0,32 W/m°K 0,27 W/m°K 0,25 W/m°K Tensile strength (kPa) 30 70 90 110 Häufig gestellte Fragen (FAQ)

How does Cerablanket™ differ from conventional insulation materials?

It withstands higher temperatures, offers lower thermal conductivity, and remains flexible even after repeated heating cycles.

Is Cerablanket™ moisture-resistant?

Yes – it is chemically stable and non-hygroscopic. However, condensation should be avoided to prevent corrosion on metallic parts.

How is Cerablanket™ cut or installed?

t can be easily cut with industrial scissors or knives.

-

Since 2001, KS Kneissl & Senn Technologie GmbH

has been producing insulation materials and seals for a wide range of applications up to a temperature range of 1600 °C. A diverse range of machinery (CNC 5-axis milling, plotting, punching, sewing, water jet cutting, vacuum forming, etc.) enables us to shape a wide variety of materials for you. The main materials include: glass fibers, aramid fibers, mineral fibers, biosoluble fibers, ceramic fibers, silicate fibers, vermiculite, calcium silicate, microporous materials, elastomers (rubber, silicone, silicone foam, etc.), etc.

The company has been ISO9001 certified since 2009, currently in accordance with the 2015 revision of the standard.