Calcium silicate

Is a white odorless solid which is practically insoluble in water. In its natural form it can be found in the mineral wollastonite (CaSiO3).

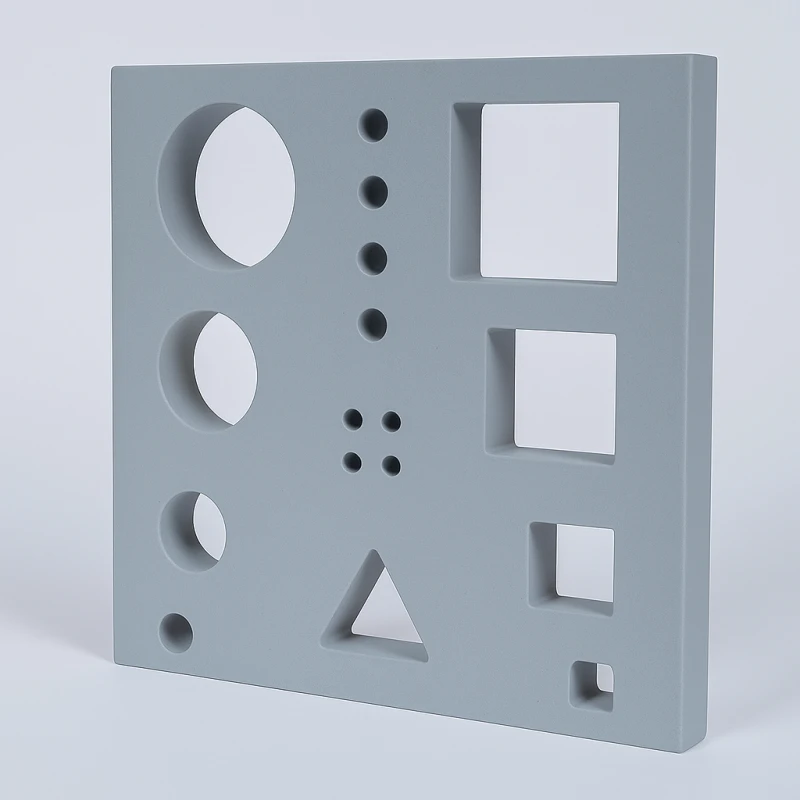

- PRODUCT VARIATIONS

- Boards | Moldings

-

Calcium silicate - high-temperature insulation material for industry & refractory construction

Calcium silicate is a lightweight, pressure-resistant, high-temperature insulation material and is used as economical backing insulation in numerous industrial and refractory applications. Due to its excellent thermal and mechanical properties, calcium silicate is ideal for high-temperature applications up to approx. 1100 °C.

The material has proven itself in particular in industrial furnace and dryer construction, in plant and apparatus construction, in the cement industry, the petrochemical industry and in domestic fireplaces.

Properties & advantages of calcium silicate

Very good thermal insulation with low thermal conductivity

High thermal stability and good compressive strength

Low heat storage for energy-efficient processes

Low bulk density - light and easy to handle

Non-combustible and highly temperature-resistant

Easy to process (sawing, drilling, milling)

Large-format boards for economical processing

Durability & processing

- Calcium silicate is resistant to reducing protective gases, including

- Hydrogen (H₂)

- Carbon monoxide (CO)

- Methane (CH₄)

- Ammonia (NH₃)

- Nitrogen (N₂)

For applications in combination with refractory concretes, the use of a hydrophobic barrier primer is recommended to reduce the penetration of mixing water and avoid additional barrier layers.

Calcium silicate - high-temperature insulation material for industry & refractory construction

Calcium silicate is a lightweight, pressure-resistant, high-temperature insulation material and is used as economical backing insulation in numerous industrial and refractory applications. Due to its excellent thermal and mechanical properties, calcium silicate is ideal for high-temperature applications up to approx. 1100 °C.

The material has proven itself in particular in industrial furnace and dryer construction, in plant and apparatus construction, in the cement industry, the petrochemical industry and in domestic fireplaces.

Frequently asked questions (FAQ)

Does calcium silicate absorb moisture?

Does calcium silicate absorb moisture? Calcium silicate is capillary-active and can absorb moisture. When used in conjunction with fireproof concrete or damp materials, a hydrophobic barrier primer is recommended to reduce water penetration.

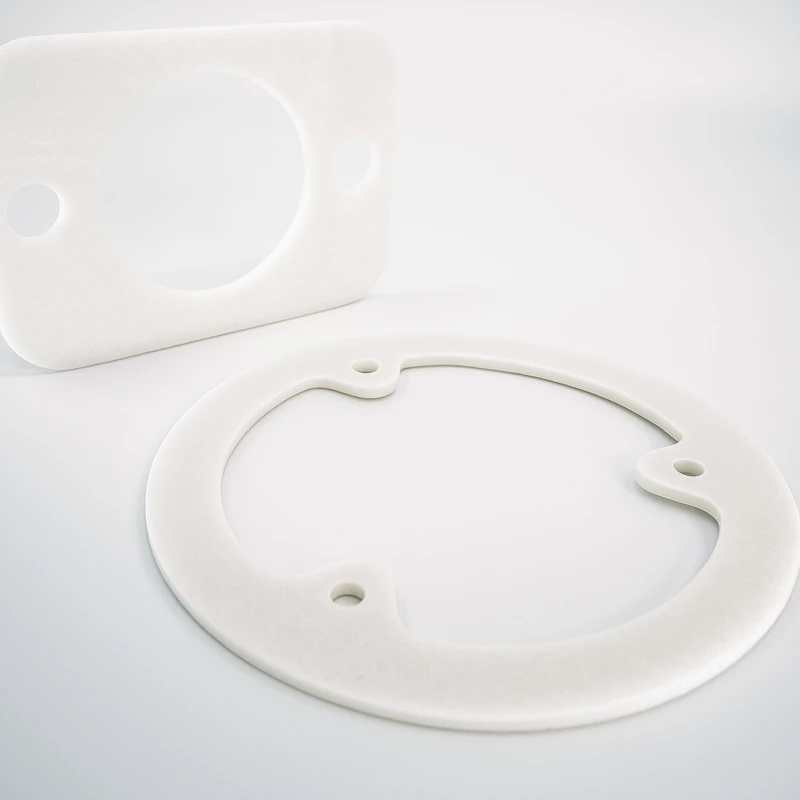

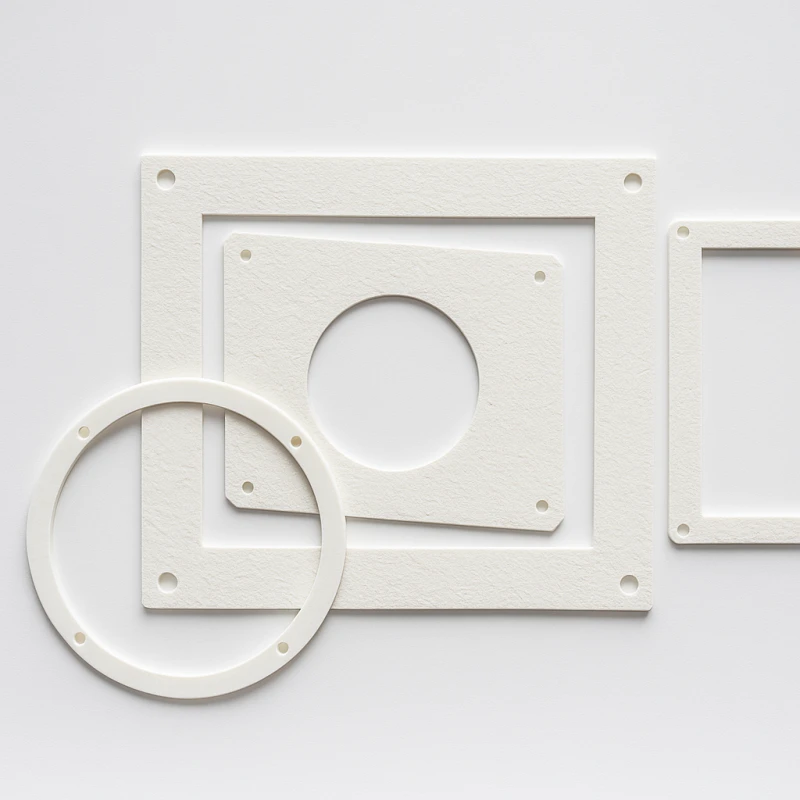

How can calcium silicate be processed?

Calcium silicate is easy to work with and can be sawn, drilled, or milled using standard tools. This enables quick and economical installation.

In what forms is calcium silicate available?

Calcium silicate is generally available in sheet form. In addition, molded parts (milled) can be supplied on request for specific projects.

Can calcium silicate be combined with other insulation materials?

Yes, calcium silicate is often used in combination with other high-performance insulation materials to achieve particularly low heat loss and compact designs.

-

Senn Group Information Catalog

Refractories, seals, foundry supplies, conveyor chains, compensators, plain bearings, lubricants, metal parts, and logistics/FTL

-

Since 2001, KS Kneissl & Senn Technologie GmbH

has been producing insulation materials and seals for a wide range of applications up to a temperature range of 1600 °C. A diverse range of machinery (CNC 5-axis milling, plotting, punching, sewing, water jet cutting, vacuum forming, etc.) enables us to shape a wide variety of materials for you. The main materials include: glass fibers, aramid fibers, mineral fibers, biosoluble fibers, ceramic fibers, silicate fibers, vermiculite, calcium silicate, microporous materials, elastomers (rubber, silicone, silicone foam, etc.), etc.

The company has been ISO9001 certified since 2009, currently in accordance with the 2015 revision of the standard.