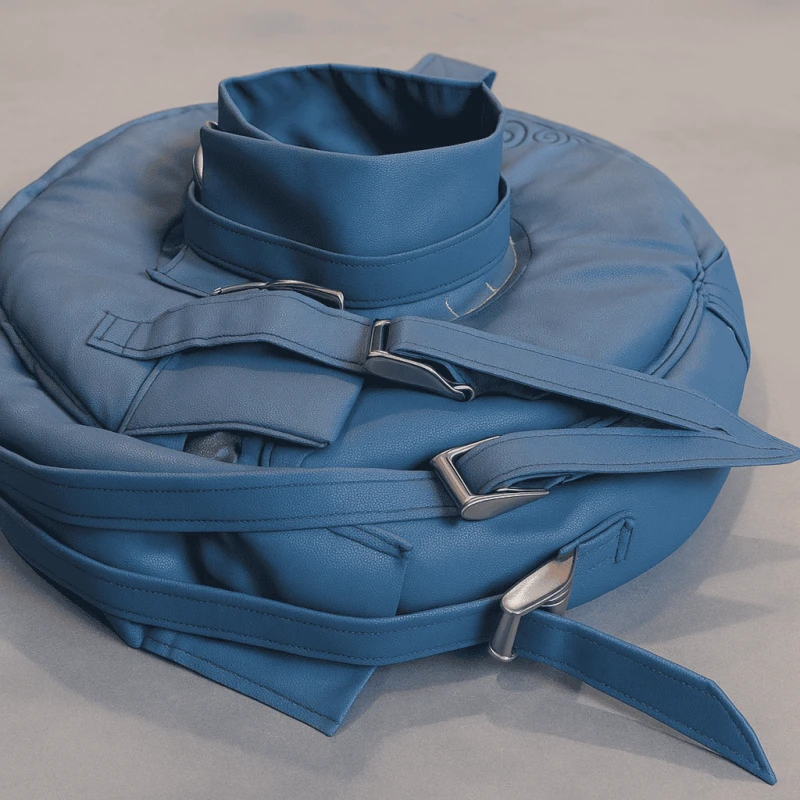

Textile confection & insulation

RBS textile confection and insulation sleeves made of high-temperature-resistant fabrics are used in a wide variety of industries for two main reasons.

- PRODUCT VARIATIONS

- Manufacture according to customer specifications

-

Temperature resistant

Depending on material composition, application temperatures up to 1260°C.

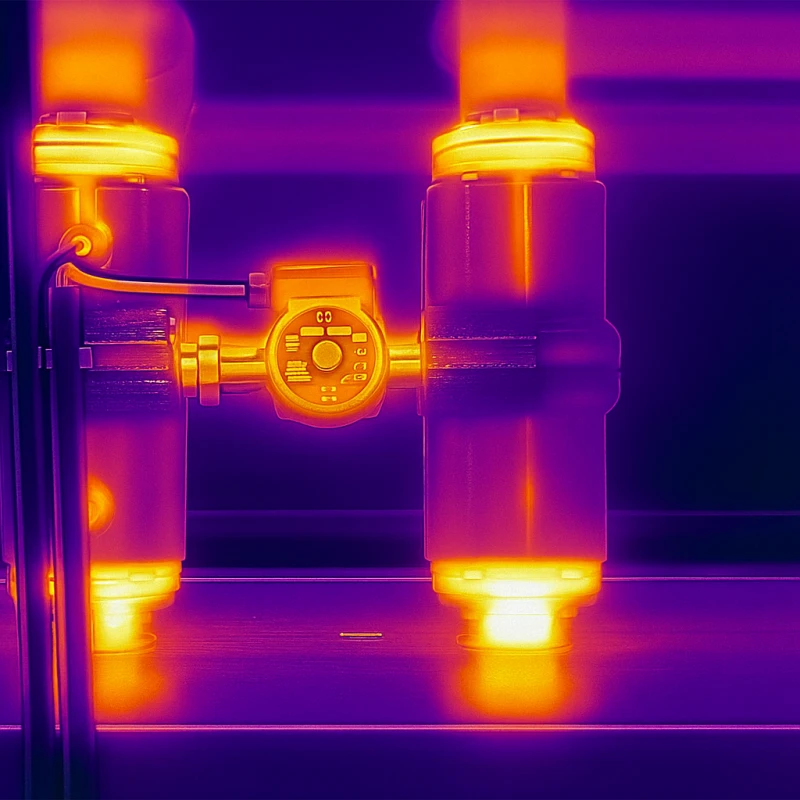

Energy efficiency

Increasing energy efficiency in areas where other insulation is not possible.

Contact protection

Contact protection to increase work safety.

Installation

CHARACTERISTICS

RBS textile confection and insulation sleeves made of high-temperature-resistant fabrics are used in a wide variety of industries for two main reasons:

- Increase in energy efficiency in areas where other materials cannot be used for insulation

- As contact protection to increase work safety

Regardless of whether in pipeline construction, for large and small engine production or in exhaust gas treatment, RBS technical assemblies stand for a long service life and, if necessary, can be exchanged with innovative lashing and tensioning systems without great effort.

Benefits

- High temperature resistance

- energy efficiency

- contact protection

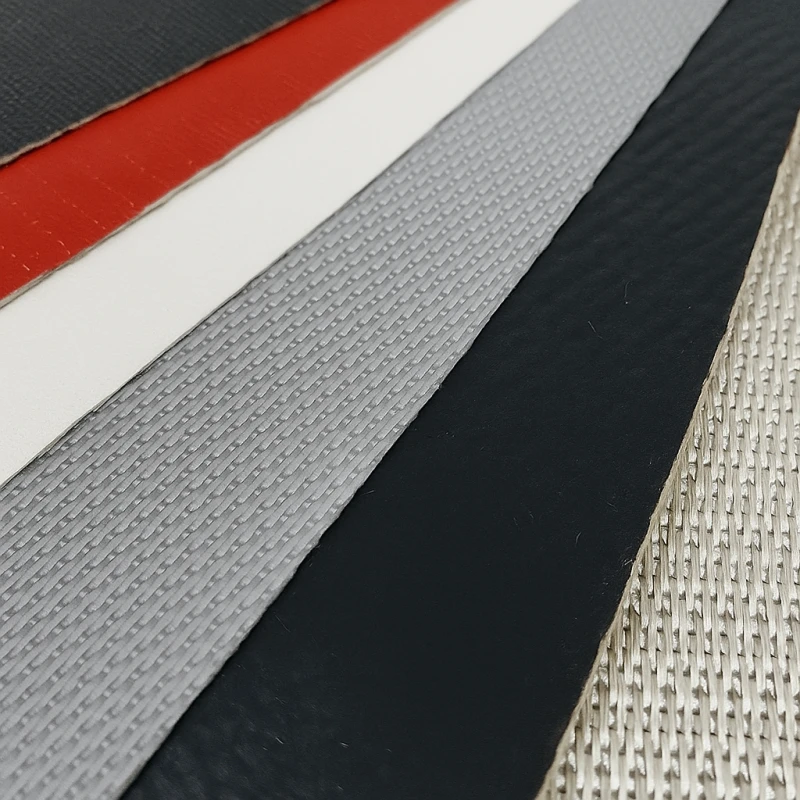

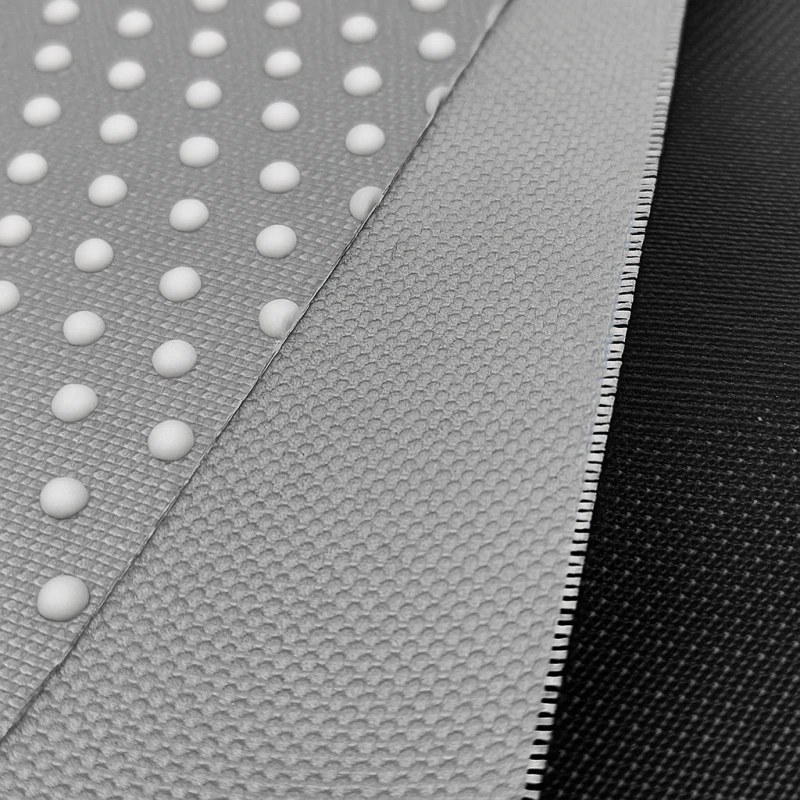

- Made of various high temperature resistant fabrics

- For pipeline construction, large and small engine production or exhaust gas treatment

- Long service life

- Innovative lashing and tensioning systems easy to exchange

-

Senn Group Information Catalog

Refractories, seals, foundry supplies, conveyor chains, compensators, plain bearings, lubricants, metal parts, and logistics/FTL

-

Since 2001, KS Kneissl & Senn Technologie GmbH

has been producing insulation materials and seals for a wide range of applications up to a temperature range of 1600 °C. A diverse range of machinery (CNC 5-axis milling, plotting, punching, sewing, water jet cutting, vacuum forming, etc.) enables us to shape a wide variety of materials for you. The main materials include: glass fibers, aramid fibers, mineral fibers, biosoluble fibers, ceramic fibers, silicate fibers, vermiculite, calcium silicate, microporous materials, elastomers (rubber, silicone, silicone foam, etc.), etc.

The company has been ISO9001 certified since 2009, currently in accordance with the 2015 revision of the standard.