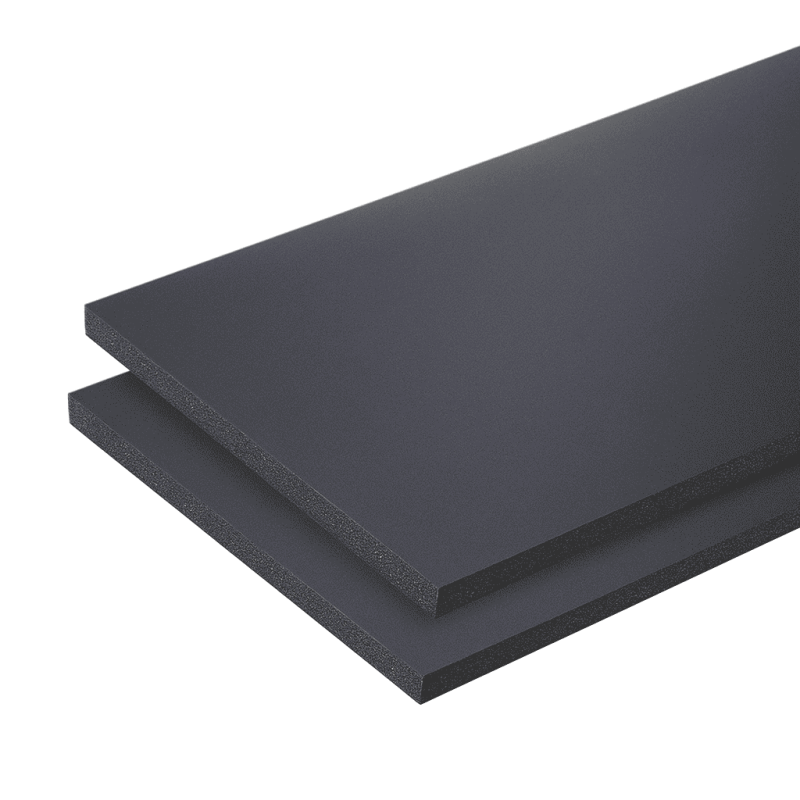

AF/Armaflex® sheet & blanks

AF Armaflex® is the professional flexible insulation material for long-term prevention of condensation and energy loss. Thanks to its stable thermal conductivity from –50°C to +110°C and integrated MICROBAN® protection, it offers reliable protection against mold and corrosion under insulation (CUI).

- Type

- AF/Armaflex sheet

- Executions

- endless | self-adhesive | endless self-adhesive

-

Thermal conductivity

Stable thermal conductivity for temperatures ranging from –50°C to 110°C.

MICROBAN® protection

First flexible insulation material protected with MICROBAN®.

Various designs

Various designs available (self-adhesive, continuous, continuous self-adhesive).

Properties

AF/Armaflex® is the professional flexible insulation material for long-term reliable condensation prevention. The optimal combination of very low thermal conductivity and extremely high water vapor diffusion resistance helps to permanently prevent energy loss and water vapor penetration and reduces the risk of corrosion under the insulation. AF/Armaflex is the first flexible insulation material to feature MICROBAN® technology. When microbes come into contact with the insulation surface, MICROBAN® protection penetrates the cell walls of the microorganism, rendering it non-functional and unable to grow or multiply. This gives AT/Armaflex products additional resistance to mold and mildew. AT/Armaflex products are used to insulate and protect pipes, air ducts, and containers in refrigeration and air conditioning systems as well as process engineering systems, to prevent condensation and save energy, and to reduce structure-borne noise transmission in water and wastewater installations.

Why AF Armaflex®? – Your advantages at a glance

- Stable thermal conductivity for consistent energy efficiency

- Application temperature: –50°C to +110°C

- MICROBAN® protection: actively combats microbes, mold, and mildew

- Integrated water vapor barrier: prevents moisture penetration

- Corrosion protection: minimizes CUI risk under the insulation

- Available as: self-adhesive, continuous, and continuous self-adhesive

- Highly flexible: for sheet goods and custom cuts

Areas of application

AF Armaflex® is used to insulate and protect pipes, air ducts, and tanks in refrigeration and air conditioning systems, as well as in process engineering plants. Ideal for preventing condensation, saving energy, and reducing structure-borne noise transmission in water and wastewater installations.

MICROBAN® Technologie – dauerhafter antimikrobieller Schutz

Als erster flexibler Dämmstoff mit MICROBAN® Technologie bietet AF Armaflex® einen entscheidenden Vorteil: Der aktive Schutz dringt in die Zellstruktur von Mikroorganismen ein und verhindert deren Wachstum – für saubere, hygienische Oberflächen über die gesamte Lebensdauer.

Frequently asked questions (FAQ)

What temperatures can AF Armaflex® withstand?

The insulation material is temperature-resistant from –50°C to +110°C, making it ideal for refrigeration and air conditioning systems.

What does MICROBAN® protection do?

It actively protects the insulation from microbes, mold, and bacteria—for greater hygiene and durability.

Are there self-adhesive versions?

Yes, AF Armaflex® sheets are also available in self-adhesive and continuous self-adhesive versions.

-

Downloads

KS Technologie product catalog

Refractory | Seals | Foundry supplies | Conveyor chains | Chesterton

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

The company has been certified according to ISO9001 since 2009, currently according to the 2015 standard revision.