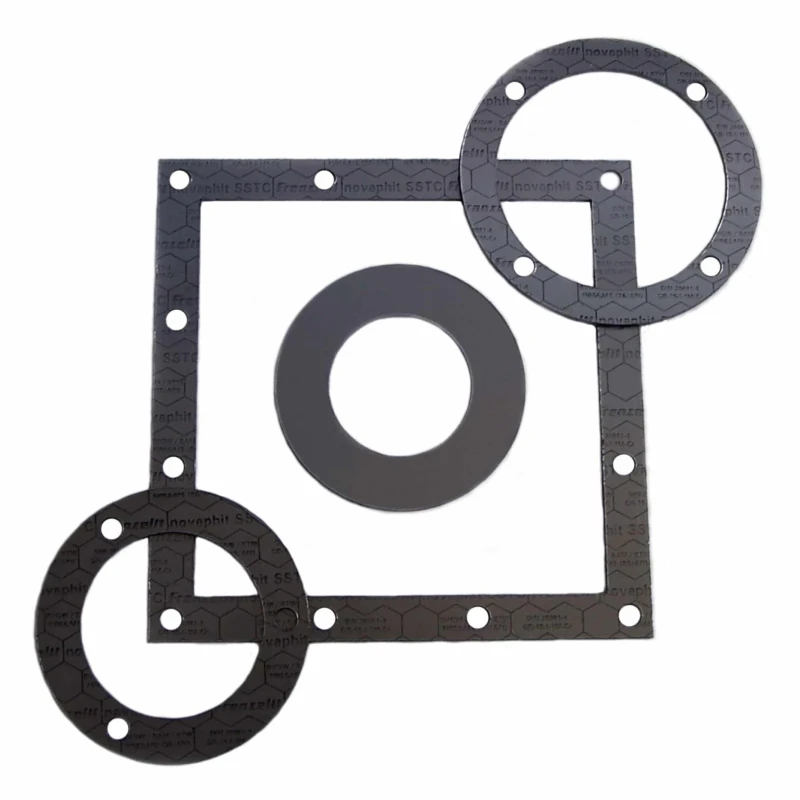

Flange seals® (flanged seals)

Based on high-quality, refined phlogopite mica, which is far superior to other types of mica in terms of temperature resistance.

-

Introduction

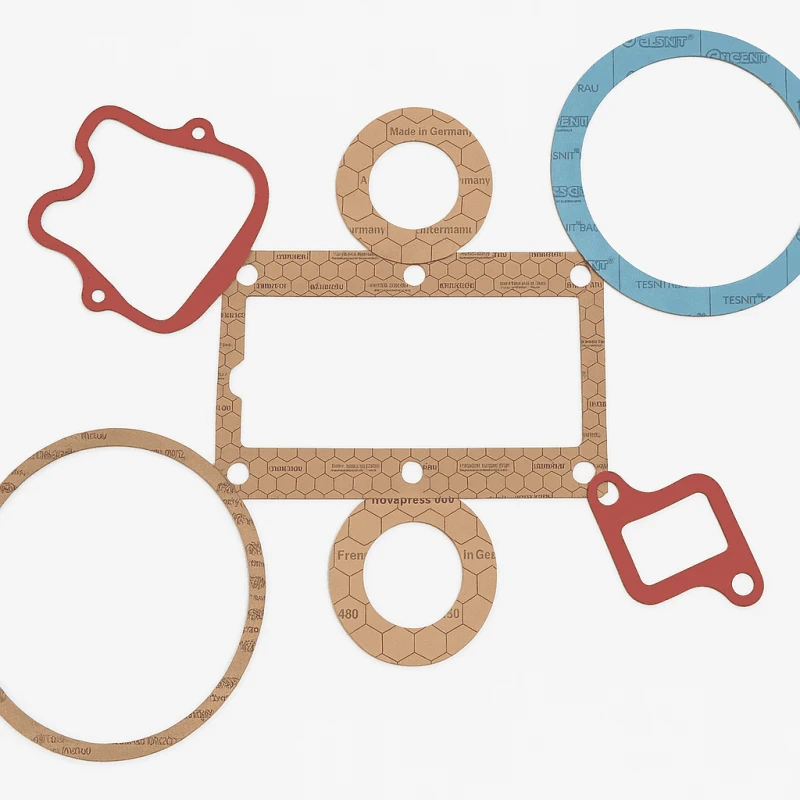

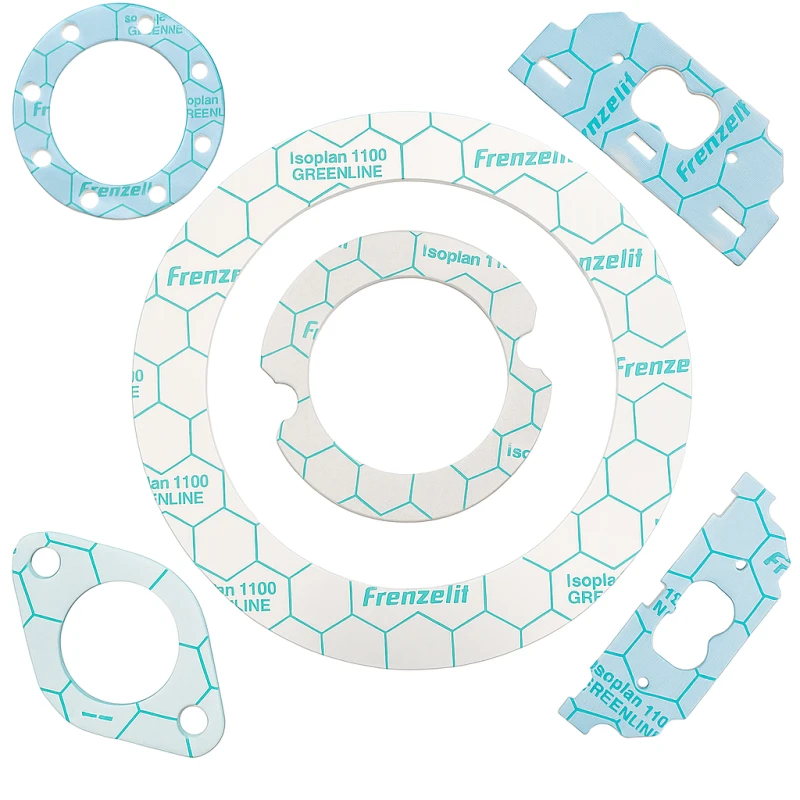

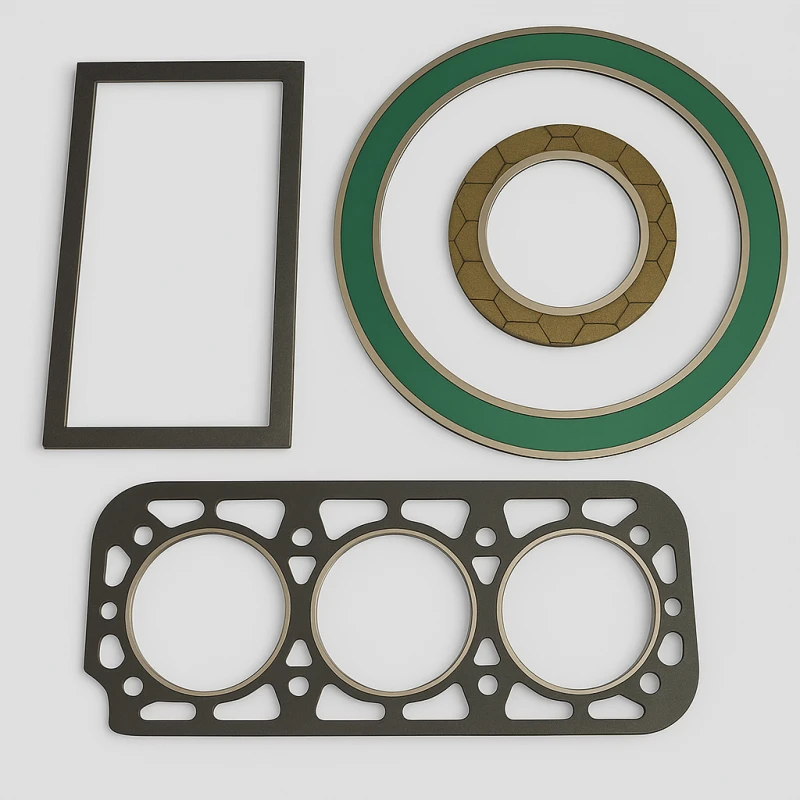

Flanged seals—also known as flanged gaskets—combine the elasticity of soft materials with the protection of a metal casing. The result: greater blow-out protection, improved media and edge resistance, and safe handling during installation and operation—even under pressure and temperature changes.

Typical areas of application

Heat exchangers, process vessels, steam boilers, pipeline construction, tongue-and-groove connections, smooth/grooved flanges – wherever high pressures, high temperatures, and aggressive media occur.

Advantages at a glance

- Greater blow-out resistance (media and pressure shock resistant)

- Higher mechanical strength and stability of the sealing lip

- Protection against contamination and abrasion at the sealing edge

- Better chemical and temperature protection depending on the flange/lining material

- Easier handling during installation/service These effects are used in practice primarily in the process and petrochemical industries, power plants, and the gas industry.

(FAQ)

What is the difference between internal and external flanging?

The inner bead protects the inner sealing edge and can increase blow-out resistance in the direction of the medium, while the outer bead stabilizes and protects the outer edge. Both can be combined.

When is a welded flange recommended instead of a continuous flange?

For special dimensions or when manufacturing limits are exceeded. Modern manufacturing often uses laser welding for this purpose.

Are flanged seals compatible with standard flanges?

Yes, typically with DIN/EN/ASME dimensions, but special shapes are also possible.

-

KS Kneissl & Senn Technologie

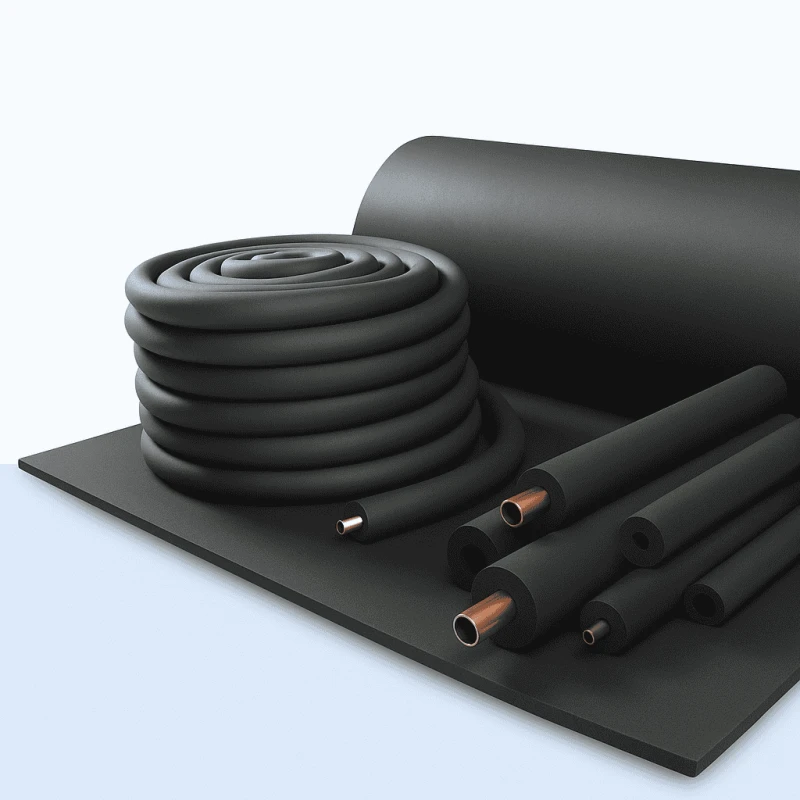

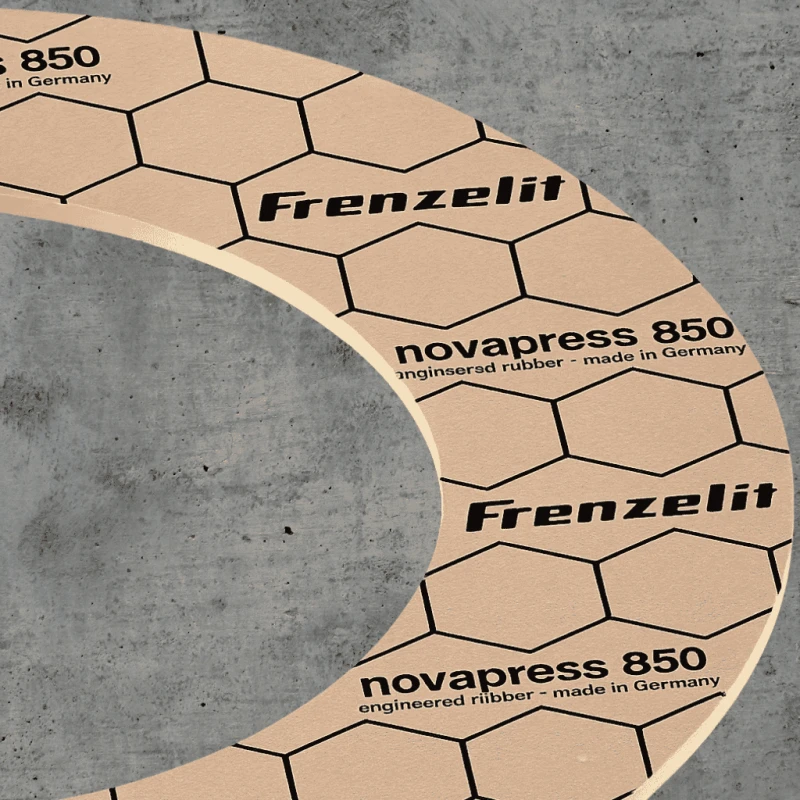

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

The company has been certified according to ISO9001 since 2009, currently according to the 2015 standard revision.