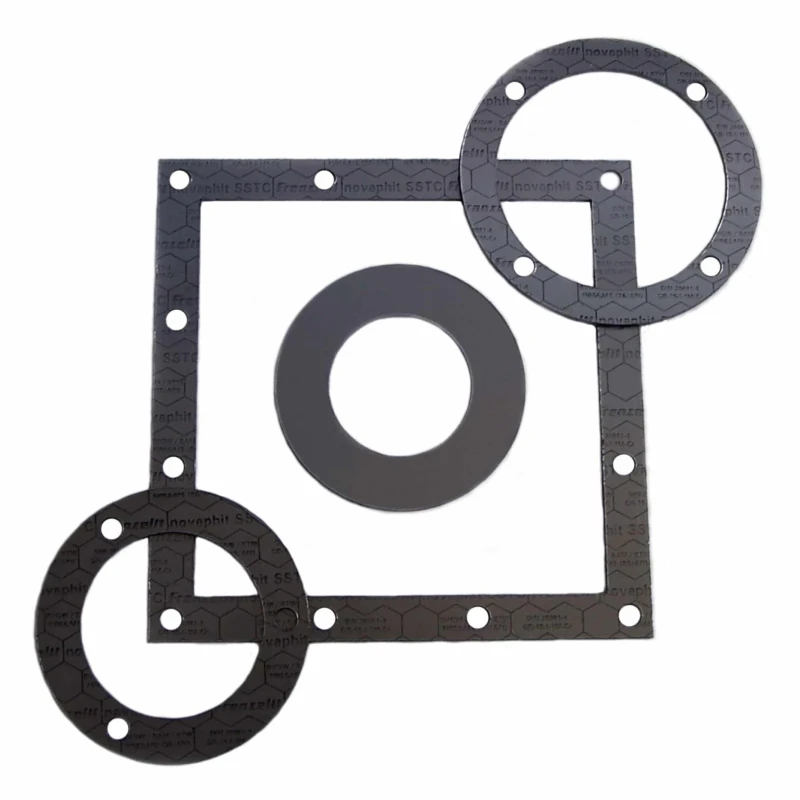

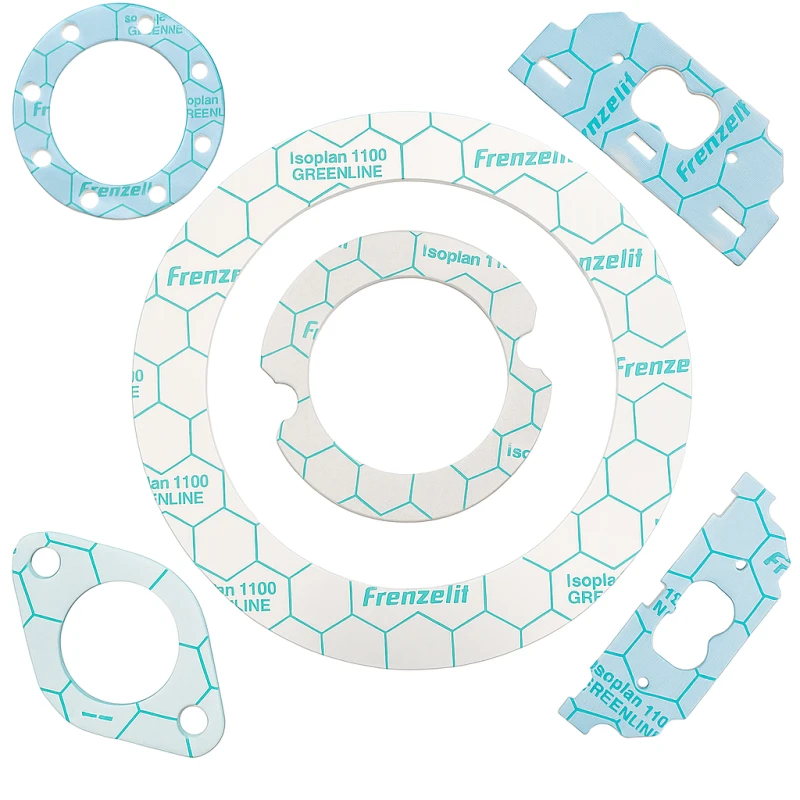

Seals made of phlogopite mica

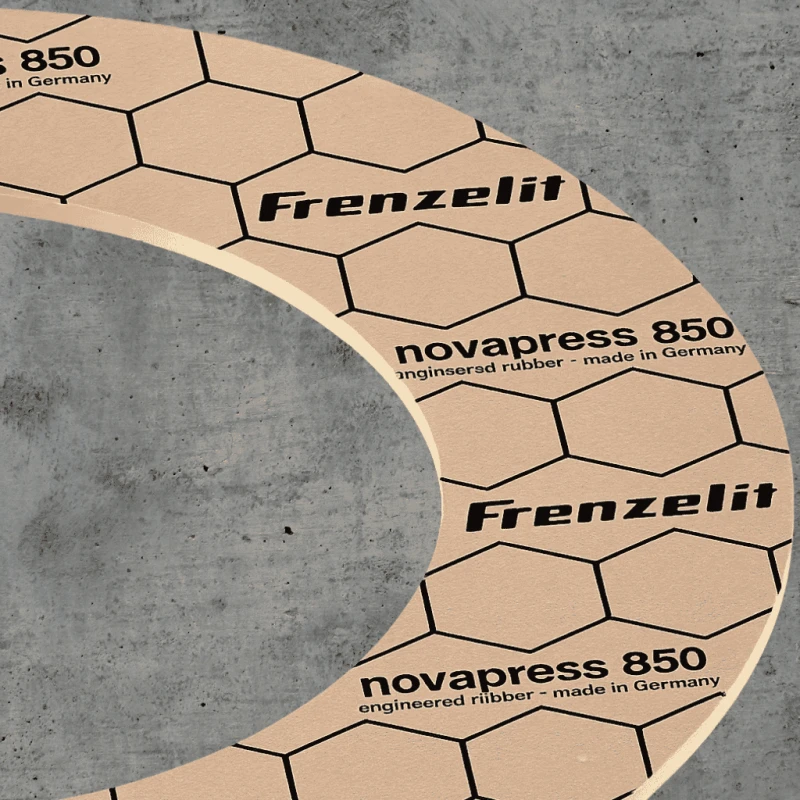

The innovative sealing material novapress® 850 from Frenzelit combines the best properties of fiber and elastomer seals.

It impresses with its extreme adaptability, high fault tolerance, and outstanding tightness—even with minimal surface pressure.

This makes novapress® 850 the perfect solution for demanding sealing applications in mechanical engineering, plant construction, gas and water supply, and the food industry.

-

Advantages of novapress® 850

Almost elastomer-like adaptability Perfect sealing even with low surface pressures or uneven sealing surfaces.

Mechanical stability like classic fiber seals High compressive strength and dimensional stability even under temperature stress.

Quantum leap in tightnessCompared to conventional fiber seals – leakage rate only 0.001 mg/(s·m).

Excellent chemical resistanceSuitable for oil, fuels, refrigerants, gas, and drinking water.

Certifications & approvals: EC 1935/2004, FDA, DVGW, W270, WRAS, HTB DIN 30653.

Made in Germany – with Gasket Code Technology: Each gasket is uniquely traceable, guaranteeing tested quality.

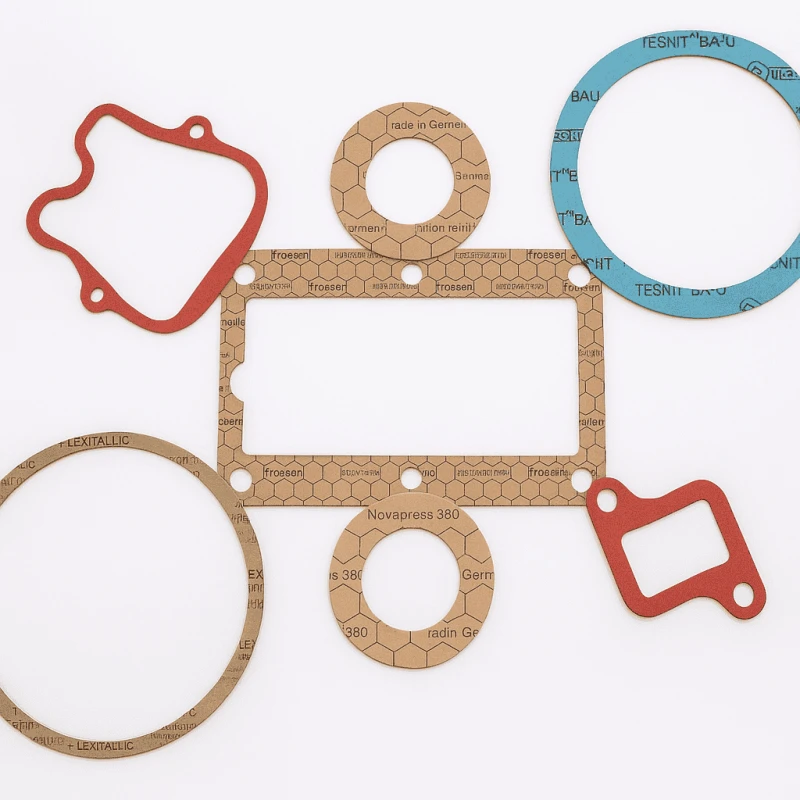

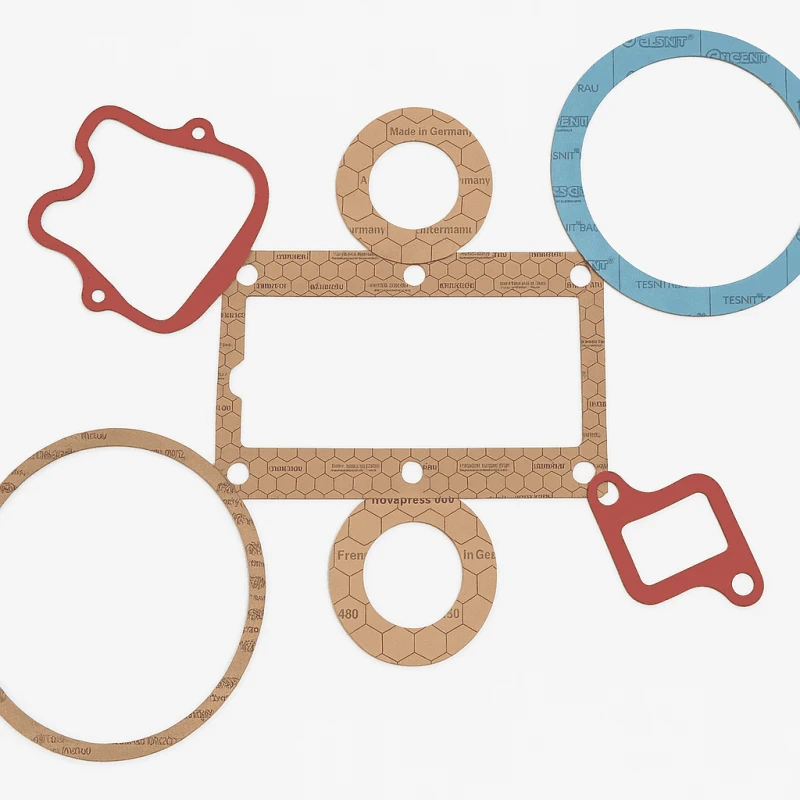

Areas of application

ovapress® 850 is ideal for applications where conventional fiber or rubber seals reach their limits:

- Gearbox and cover seals

- Pump and compressor housings

- Flexible or easily deformable components

- Components with large screw spacing and uneven pressure distribution

- Gas and drinking water connections

- Food processing and filling

- Applications in contact with oil, fuel, or refrigerants

Eigenschaft Wert / Bereich thickness 0,5 / 1,0 / 1,5 / 2,0 / 3,0 mm density 1,25 – 1,40 g/cm³ Pressure resistance (175 °C) 20 – 35 N/mm² Specific leakage rate 0,001 mg/(s·m) temperature range ca. –100 °C bis +200 °C Approvals EG 1935/2004, FDA, DVGW, W270, WRAS, HTB DIN 30653 Color Light brown with black honeycomb print Note: Specifications refer to standard panels with a thickness of 2 mm; other thicknesses available on request.

Warum novapress® 850?

Bei geringen Schraubenkräften oder dünnwandigen Bauteilen erreichen klassische Faserstoffdichtungen häufig nicht die nötige Dichtheit.

Gummidichtungen hingegen verlieren bei höheren Temperaturen oft ihre Stabilität.

novapress® 850 schließt diese Lücke:

Weich und anpassungsfähig während der Montage – robust und dicht im Betrieb.Suitable for gas, water, and food

Gas-tight & suitable for drinking water – complies with DVGW and HTB guidelines.

Food-safe – certified according to EC 1935/2004 and FDA.

Hydrogen-tested (H₂-approved by Frenzelit) – exceptional tightness and material stability.

This makes novapress® 850 universally applicable: from gas and water supply to food production.

Häufig gestellte Fragen (FAQ)

What is novapress® 850 particularly suitable for?

novapress® 850 is ideal for low surface pressures or flexible components, e.g., gear and pump housings, covers, and flanges with large screw spacing. It combines the adaptability of an elastomer with the mechanical stability of a fiber gasket, thus achieving a very high level of tightness.

What media and temperatures does the material cover?

The material is resistant to oils, fuels, and refrigerants and is suitable for gas and drinking water applications. The typical operating range is approximately –100 °C to +200 °C (depending on the application). For specific media/temperatures, we recommend testing on a case-by-case basis based on the operating conditions.

novapress® 850 complies with EC 1935/2004 and FDA (food contact) as well as DVGW, W270, WRAS, and HTB DIN 30653 (gas/drinking water), among others. This makes the material an excellent choice for both utility companies and the food industry.

In what thicknesses and formats is novapress® 850 available?

Typical thicknesses are 0.5 / 1.0 / 1.5 / 2.0 / 3.0 mm. Panel formats are standard for the industry (e.g., 1000×1500 mm, 1500×1500 mm, 3000×1500 mm). We manufacture special thicknesses and cut-to-size panels on request—including series and individual part production according to drawings.

-

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

The company has been certified according to ISO9001 since 2009, currently according to the 2015 standard revision.