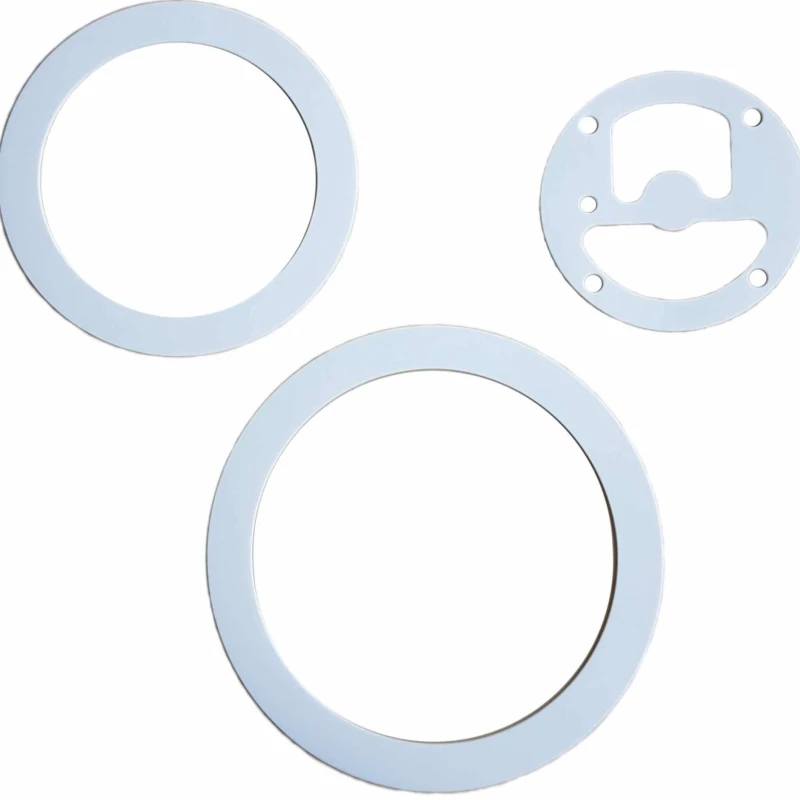

Soft seals® – reliable sealing solutions for every application

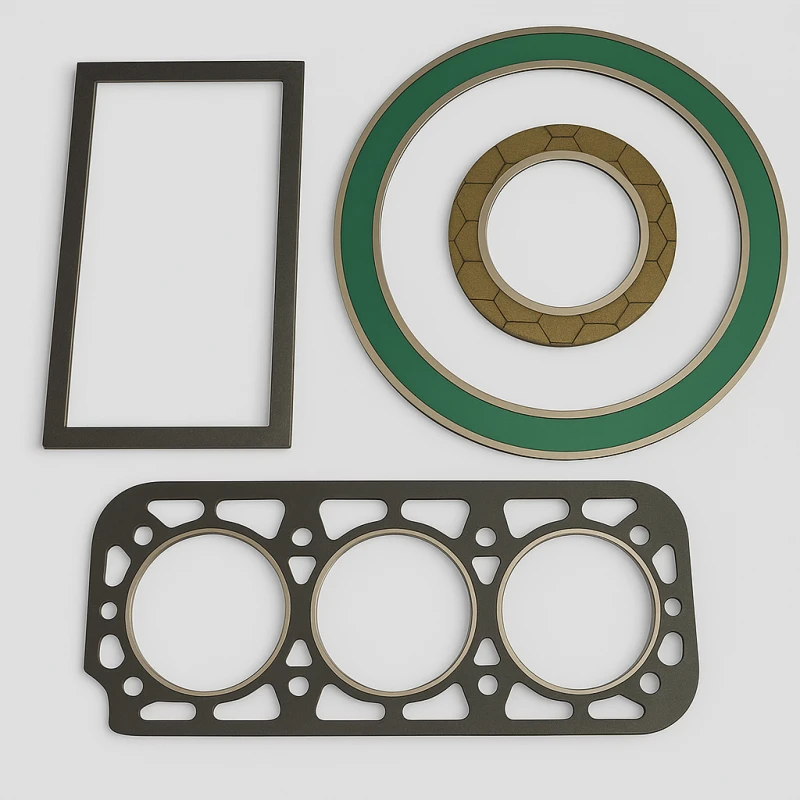

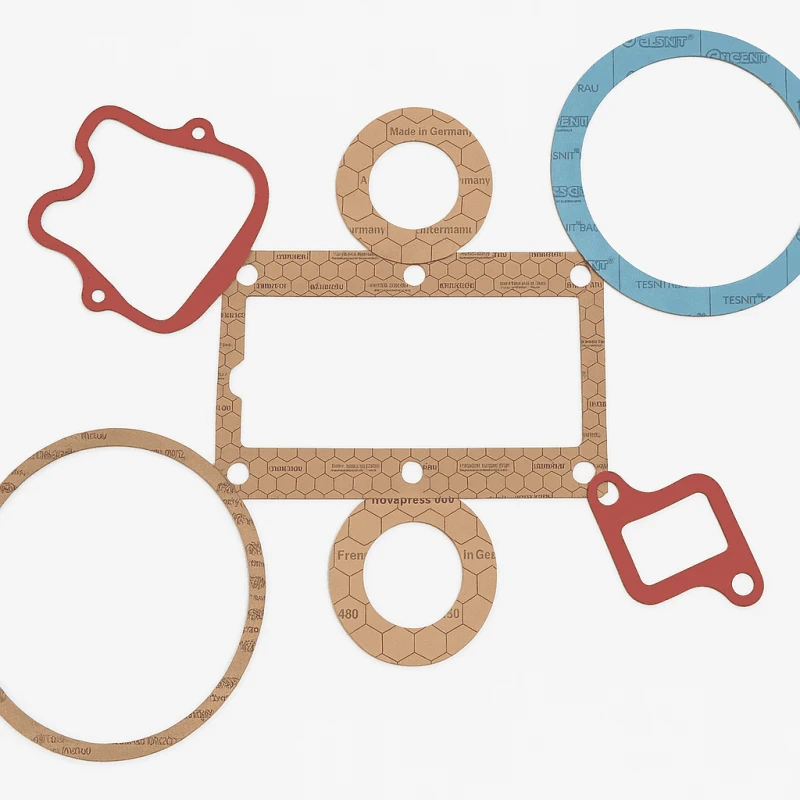

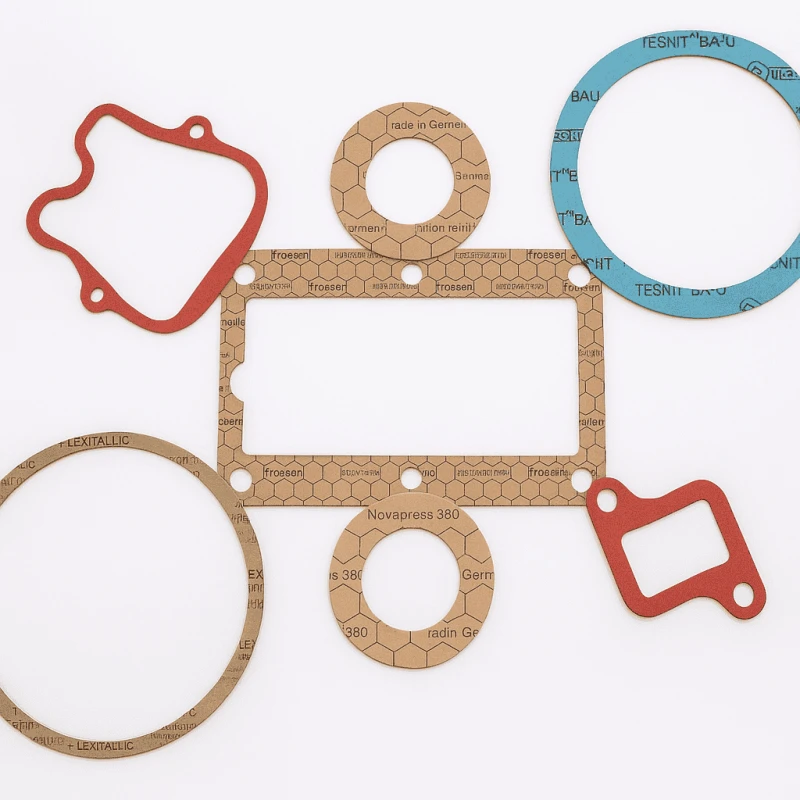

Soft material gaskets are versatile sealing materials that provide secure and durable sealing in countless industrial applications. They are made from high-quality soft materials such as cellulose, aramid, glass, carbon, or rock wool—combined with specially formulated fillers.

This composition gives them excellent chemical resistance, pressure stability, and a long service life.

-

Features & advantages of our soft seals

High sealing effect at different temperatures and media

Chemical and pressure resistance

Easy to process and adaptable to any flange shape

Wide range of material combinations (e.g., aramid, glass, cellulose)

Cost-effective compared to metal gaskets

Our soft seals are ideal for apparatus engineering, pipeline construction, the chemical industry, and energy and plant engineering.

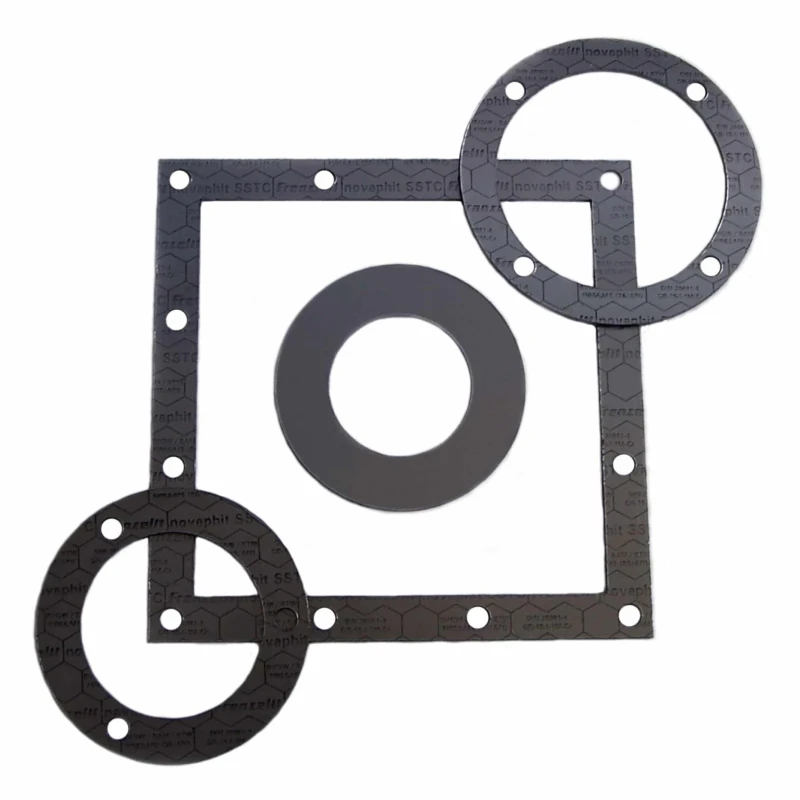

Customized manufacturing

Whether one-off production or series production, we manufacture soft material seals according to your technical requirements. Thanks to modern cutting and punching technology, we guarantee precise results and short delivery times.

Optional: Send us your drawing or dimensions, and we will create your custom sealing element.

Technical materials

Our seals are made of high-quality soft materials such as:

Cellulose fibers – ideal for water and oil applications

Aramid fibers – high temperature and pressure resistance

Glass fibers – excellent chemical resistance

Carbon and rock wool fibers – outstanding thermal conductivity

Typical areas of application

Chemical plants

Piping systems

Apparatus and vessel construction

Heating and sanitary engineering

Mechanical engineering

Material Properties Area of application cellulose Good oil and water resistance standard applications aramid High temperature and pressure stability Chemistry & Energy fiber optics Chemically resistant & dimensionally stable process industry Carbon / rock wool Thermally conductive & robust high-temperature applications Frequently asked questions (FAQ)

What are soft seals?

Soft seals are made of fiber-reinforced materials such as cellulose, aramid, or glass fibers. They are used to seal between two surfaces and prevent leaks in pipes, equipment, or machines.

What temperatures are soft seals suitable for?

Depending on the material, soft seals can be used at temperatures up to approx. 300 °C. High-quality aramid or carbon variants can also withstand higher temperatures.

Which media can be sealed with soft seals?

They are suitable for water, oil, steam, gases, and many chemicals. The exact material should be matched to the medium.

Can I have soft seals custom-made?

Yes – we manufacture custom-made seals based on drawings or CAD files, both for individual items and for series production.

How long do soft seals last?

The service life depends on temperature, pressure, and medium. Under optimal conditions, they can provide reliable sealing for several years.

-

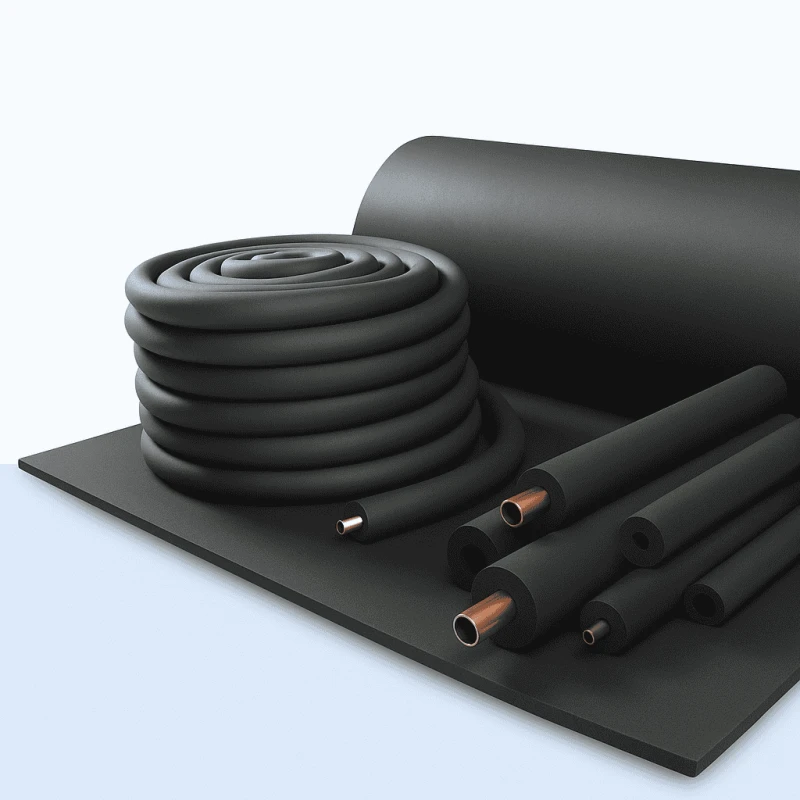

KS Kneissl & Senn Technologie

KS Kneissl & Senn Technologie GmbH has been producing insulation materials and seals for a wide variety of applications up to a temperature range of 1600 ° C since 2001. A diverse machine park (CNC 5-axis milling, plotting, punching, sewing, water jets, vacuum forming, etc.) enables us to do a variety of things Materials in shape for you bring to. The main materials include materials such as: glass fibers, Aramid fibers, mineral fibers, Biosoluble fibers, Ceramic fibers, silicate fibers, Vermiculite, Calcium silicate, Microporous materials, Rubber Material (Rubber, silicone, Silicone sponge, etc.), etc.

The company has been certified according to ISO9001 since 2009, currently according to the 2015 standard revision.